In the fast-paced world of modern manufacturing, time is more than just a ticking clock. It’s the backbone of productivity and success across all industry levels. Every second counts and every second saved has a tangible impact on output and efficiency.

In this industry, Quick mold change (QMC) is an emerging solution — transforming manufacturing efficiency and agility.

It aims to transform how the manufacturing industry approaches the task of switching molds within machinery. This challenge, long known for its intricate and time-consuming nature using conventional methods, becomes remarkably more manageable when employing QMC.

As a result, manufacturers can dramatically reduce downtime, a crucial efficiency factor on the manufacturing floor.

Continue reading to discover how this has promoted substantial improvements in efficiency and productivity in recent years.

Understanding Mold Change in Manufacturing

Molds are the cornerstone of production in countless manufacturing industries, from automotive parts to consumer goods. They are the templates that give materials their desired shape and functionality.

The process of changing these molds, however, has traditionally been a bottleneck in production.

The Traditional Mold Change Process

Traditionally, changing a mold involves several steps: shutting down the machine, cooling the existing mold, manually removing it, installing the new mold, and then reheating.

This process is not only time-consuming, but also requires significant manual labor and precision.

The downtime during this transition can lead to considerable production delays, a challenge in an industry where time equates to productivity and profit.

How the Quick Mold Change Process Changed Manufacturing

Because a lot of businesses encountered production delays, doing a quick mold change revolutionizes this process. It’s a system designed to minimize the time and effort of switching molds.

Here’s how it contrasts with the traditional process:

- Reduced Downtime: QMC systems often incorporate pre-heating and rapid cooling technologies, slashing the time needed to change molds.

- Automation: Many QMC systems use hydraulic or magnetic clamping systems, reducing manual labor and the chance of human error.

- Enhanced Safety: With less manual intervention, the risk of accidents during mold changes decreases significantly.

The advent of QMC marks a significant stride in manufacturing efficiency. It accelerates production cycles and enhances the flexibility of the manufacturing process, which allows for quicker responses to market demands.

It’s an innovation that propels industries towards a future of increased efficiency and adaptability.

Key Components of Quick Mold Change Systems

Quick mold change systems comprise several key components, each playing a crucial role in enhancing the efficiency and speed of the mold-changing process.

These components work together to reduce changeover time, a critical factor in maximizing production efficiency.

Clamping Systems

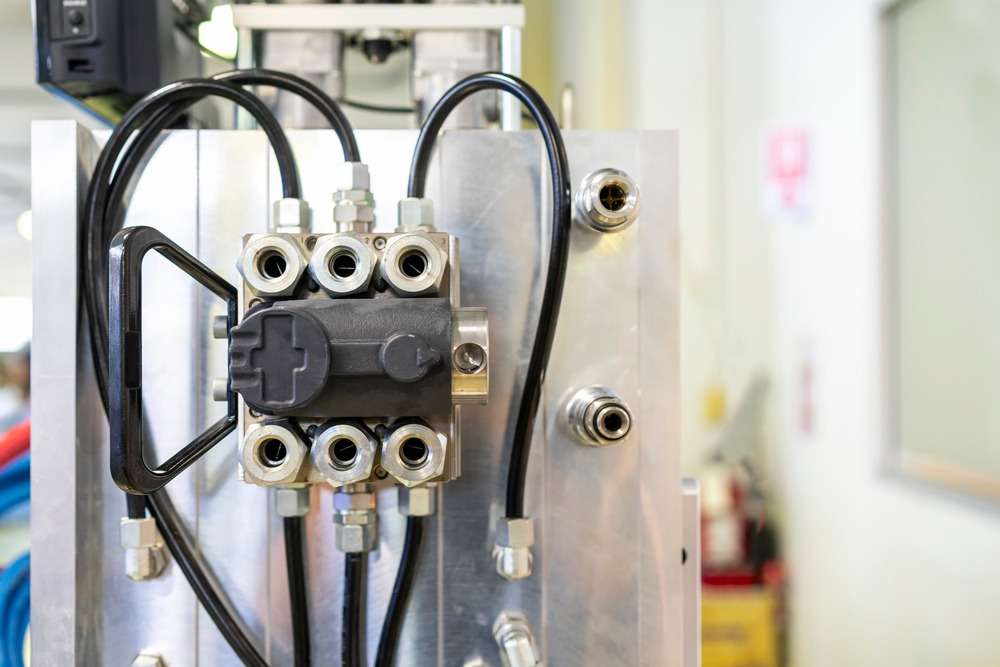

Clamping systems are at the heart of QMC, responsible for securely holding the mold in place during production and allowing for rapid release and exchange.

These systems come in various forms, such as hydraulic, magnetic, or mechanical clamps.

The primary benefit of advanced clamping systems is their ability to significantly reduce the time and effort required to secure and release molds. This efficiency is achieved through fast-acting mechanisms that can be easily controlled, minimizing downtime between production runs.

Ejector Systems

Ejector systems are crucial for quickly and safely removing the finished product from the mold, ensuring that the mold is ready for the next cycle without delay.

These systems enhance the speed of the production cycle by ensuring swift and precise ejection of parts. This reduces the time molds remain idle, thereby increasing overall operational efficiency.

Automation and Control Systems

Automation and control systems are the technological backbone of QMC, enabling precise and efficient control of the entire mold change process.

These systems allow for a more streamlined, consistent, and error-free process. Automation reduces manual intervention, lessening the risk of errors and increasing the speed of changeovers.

Control systems provide the ability to monitor and adjust the process as needed, ensuring optimal performance.

Each of these components plays a pivotal role in reducing the time and complexity involved in changing molds, thereby enhancing the overall efficiency of the manufacturing process.

By understanding these essential elements, manufacturers can better appreciate the transformative impact of QMC systems.

Benefits of Implementing Quick Mold Change

Implementing quick mold change systems is a transformative step for any manufacturing facility, offering a range of benefits that extend far beyond the immediate improvement of the mold-changing process.

Here’s how:

Increased Efficiency and Productivity

One of the most significant benefits of QMC systems is the marked increase in efficiency and productivity. By streamlining the mold change process, QMC systems enable a quicker turnaround, which means more production cycles can be completed in the same amount of time.

This increase in efficiency often leads to a corresponding rise in productivity, as machines spend less time idle and more time producing. Enhanced productivity not only boosts output but also contributes to better meeting market demands and customer needs.

Reduced Downtime and Operational Costs

Another critical advantage of QMC is the substantial reduction in downtime. Traditional mold-changing processes can take hours, during which production comes to a standstill. QMC systems can reduce this time to minutes, significantly cutting down on periods of inactivity.

This reduction in downtime directly translates into lower operational costs, as less time is wasted and resources are utilized more effectively. Moreover, the reduced need for manual labor in the mold change process can lead to further cost savings.

Enhanced Flexibility in Production

Flexibility is a crucial factor in today’s fast-paced market, and QMC systems provide this by allowing for quicker and easier mold changes. This flexibility means that manufacturers can respond more rapidly to changes in market demand, enabling them to switch between different product lines or customize products with greater ease.

Adapting quickly to new requirements is a significant competitive advantage in any industry.

QMC systems are not just about speeding up a single process; they are about rethinking and improving the entire production cycle. By implementing these systems, manufacturers position themselves for tremendous success in a competitive and ever-evolving market.

The benefits extend from the factory floor to the broader business strategy, making quick mold change an invaluable asset in modern manufacturing.

Challenges and Considerations in Implementing QMC

While the advantages of quick mold change systems are clear, their implementation comes with its own set of challenges and considerations that must be carefully navigated.

Initial Investment and Installation Complexities

The first hurdle many manufacturers face is the initial investment required for QMC systems. These systems, with their advanced technology and components, often come with a significant price tag. Additionally, the installation of these systems can be complex, requiring a thorough overhaul of existing machinery and processes.

This step not only involves financial costs but also demands time and resources to integrate the QMC system seamlessly with the existing setup.

Training and Skill Requirements for Personnel

Another challenge lies in the training and upskilling of personnel. Implementing QMC systems often requires workers to have a different set of skills compared to traditional mold change processes.

This means extensive training is necessary to ensure that staff can effectively operate and maintain the new systems. The transition period can also affect productivity as workers adapt to the latest technology and procedures.

Safety Considerations and Best Practices

Safety is a paramount concern when introducing any new system into a manufacturing environment. QMC systems, while designed to reduce manual intervention, still require adherence to strict safety protocols to prevent accidents.

This involves not only training workers on safety best practices but also ensuring that the QMC system itself is equipped with safety features and failsafe. Regular maintenance and inspections become crucial to maintain the integrity of the system and the safety of the workforce.

Implementing QMC systems is a strategic decision that requires careful planning and consideration of these challenges. It’s a balancing act between embracing innovation and managing the transition effectively.

Despite these challenges, the long-term benefits of QMC systems often justify the initial effort and investment, paving the way for a more efficient and competitive manufacturing process.

NEED IT FIXED RIGHT NOW? PFA is REAL SERVICE™

Although most PFA products are built to size, the most critical items are maintained on-the-shelf for rapid availability. Need it to ship in 4 hours or less? We can do it! With real-time technical support, off-the-shelf products, and same day shipping, we can often have you back up and running before you’ve had your morning coffee. That’s REAL SERVICE™.

HAVE A DIFFICULT PROBLEM TO SOLVE? PFA IS THE SOLUTION.

We work with our customers to solve existing problems, and can design custom solutions when needed. With over 25 years of experience reviewing applications and providing custom products, PFA is likely to have the solution to your problem already designed. Call us today and see if we can help!

WONDERING HOW TO INCREASE PRODUCTION? PFA MEANS NO DELAYS.

With a proven off-the-shelf «lean manufacturing» solution from PFA, your application works every time. Using a KOR-LOK® Side-Action System will result in shorter design and manufacturing time and will lead to shorter concept-to-production schedules. KOR-LOK® Preloading Hydraulic Locking Cylinders and Quick Die Change (QDC) clamps are in-stock and ready to ship, so you can start saving time and money with SMED today. From spare parts to complex solutions, PFA is the answer to faster production and more profits.