When to Use:

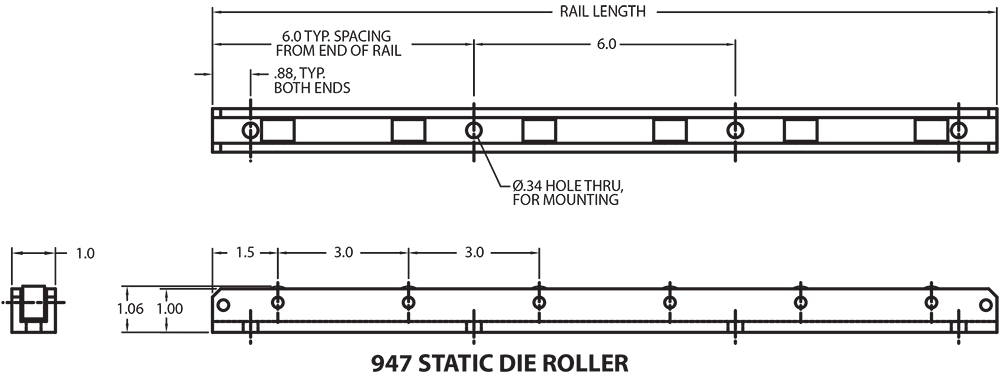

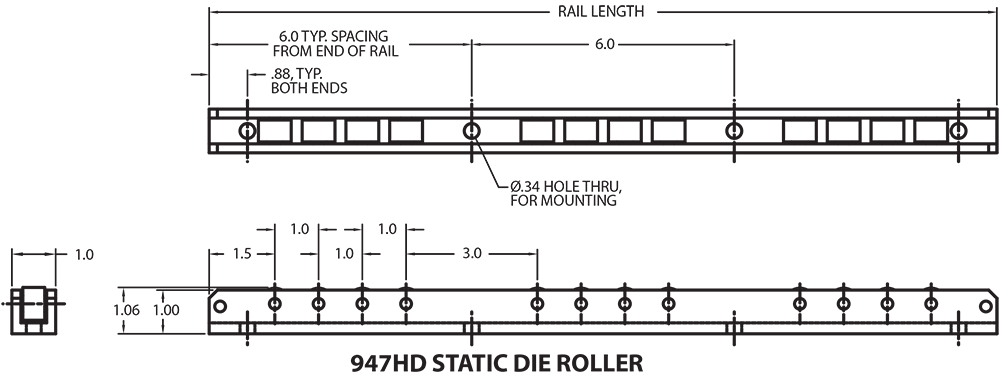

Stationary Spring Loaded Die Lifter Rails. Providing multi-directional movement, these rails (roller bars) are used for medium to lightweight dies when die density is low. They are also used when the need for mechanical only or unique layouts drive the decision process. Springs automatically lift die when clamping is removed from the die.

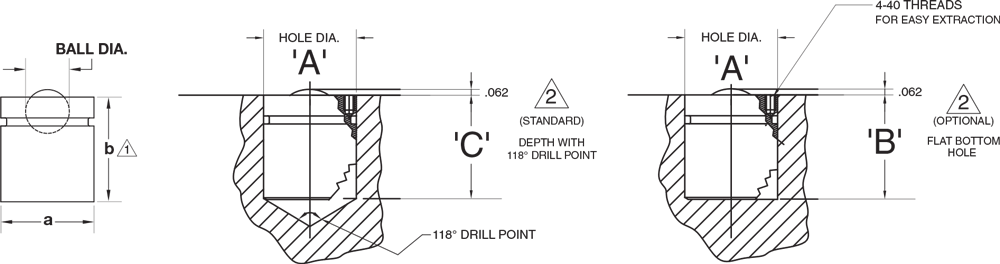

Stationary Spring Loaded Ball Cartridges. Installing an array of single ball cartridges also provides multi-directional die movement without operator involvement. Cartridges can be placed anywhere in the bolster to avoid taking up slots needed for clamps. Cartridges work great in Non-Slotted Bolster applications.

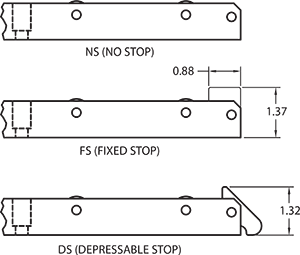

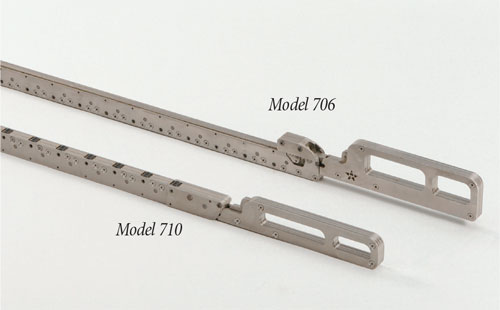

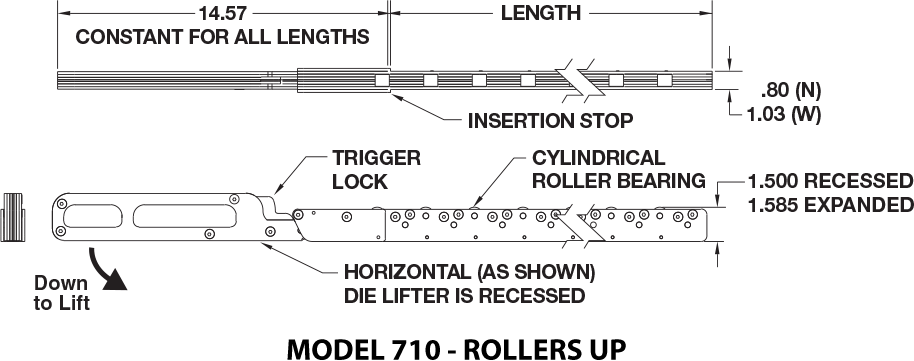

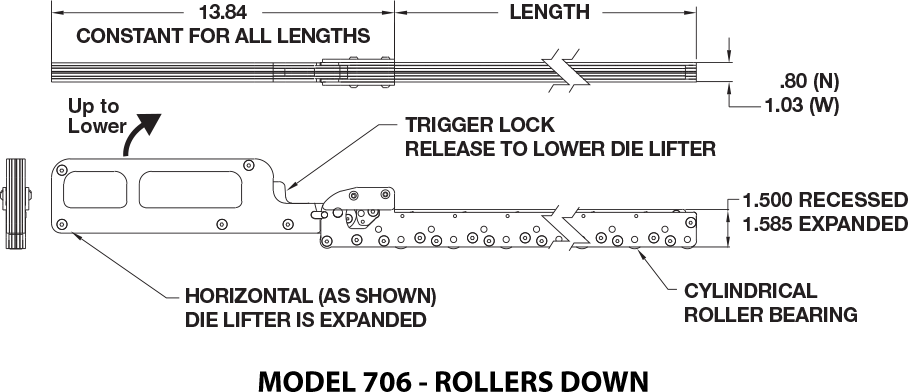

Portable Die Lifters. Hand operated lifters (roller bars) work well with common slots among presses, providing maximum ROI by allowing a single set of lifters to serve die changes on an entire group of presses.

Fixed Height Roller Bars / Pre-Rollers. Providing conveying movement only, these cam roller rails fit tight locations for easy movement of lifted dies to other locations.

How they work:

Spring loaded ball cartridges and spring loaded die lifter rails are permanently installed in the bolster. During clamping, the clamp force compresses the springs and forces the balls below the surface. When clamps are released, the spring forces lift the balls and the die with them. The die is now ready for removal/repositioning.

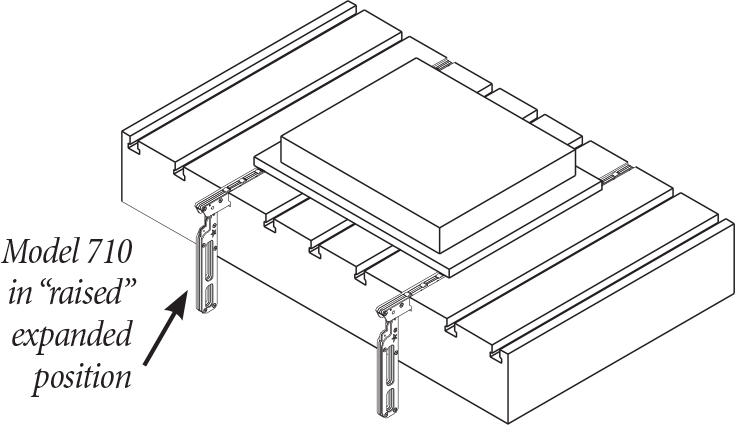

Portable die lifters provide a large mechanical advantage by multiplying hand/handle motion to lift the die. The large lever action easily lifts the die for either (1) die lifting only – insert in slot and lift the die allowing the die to be rolled onto a cart, etc. or (2) die lifting and movement onto a bolster extension, allowing die pickup with forks.