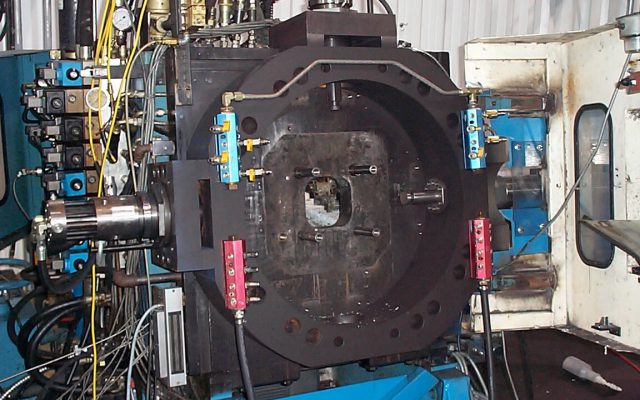

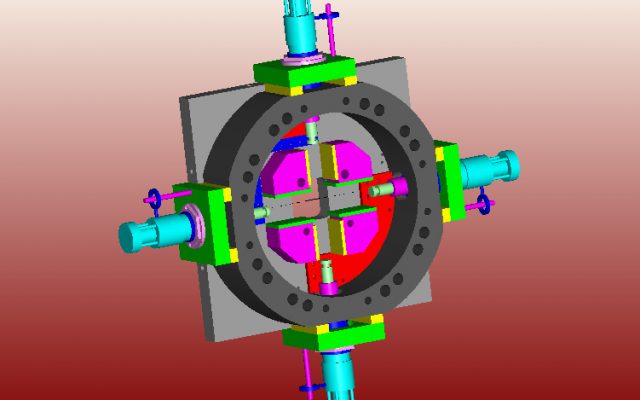

DIE-LOK™ Multi-Slide Die Casting Components are specifically designed for ease of use and adjustment on Multi-slide Die Casting Applications. Employed and evaluated as a custom solution on multiple installations for over15 years and perhaps more than 100 million cycles, this system is now also available from Techmire on the new 44LCX or as a retrofit for all 44 machines.

Advantages of the DIE-LOK™ Multi-slide System:

- Higher clamp tonnage – Preloading Hydraulic Locking Cylinders provide very high output forces that are locked into position and supported by the large support ring, which creates an extremely stiff and resilient clamping system. Rigidity and mechanical locks ensure no movement during the shot and allow for much higher shot forces than typically allowed.

- Low to Zero porosity parts – Higher clamps tonnage and increased rigidity allow for high shot speeds and pressures on commony sized parts. Parts that were once porous or difficult to cast can often be made with extremely low porosity and consistent weights. Reduction of part porosity to effectively zero and part rejection rates at or near zero is typical performance for this system.

- Excellent part shape and finish – Parts often are often cast and ready to ship when exiting the die. Several customers eliminated complete finishing lines on product lines when converting to DIE-LOK.

- Easy Setup – Control of die lengths across product lines allows for easy removal and replacement of matching die sets without the need for cylinder adjustment. If adjustment is needed, the PFA adjustment system allows for movement of shank position and preloading without disconnecting hydraulics. A simple turn of the adjustment nut changes position in a controlled manner, thus allowing clamp tonnage adjustment on the fly to adjust clamp performance.

This modular solution provides excellent clamp force, high speed, fast die change, and long life. Consider this complete interface system for zero flash low porosity parts on all your multi-slide applications. Please contact PFA for a more detailed explanation of our unique approach to multi-slide die-casting and how DIE-LOK can be used to enhance all your die casting applications. For comprehensive upgrades and new complete systems, please visit the Techmire 44LCX information page for additional information.

DIE-LOK™ Side-Action systems for standard die casting applications are high temp versions of our KOR-LOK® Side-Action systems and commonly used on high quality precision die casting molds on precision systems such as Frech® die casting machines. Contact PFA to discuss known applications and options to see if DIE-LOK is right for you.