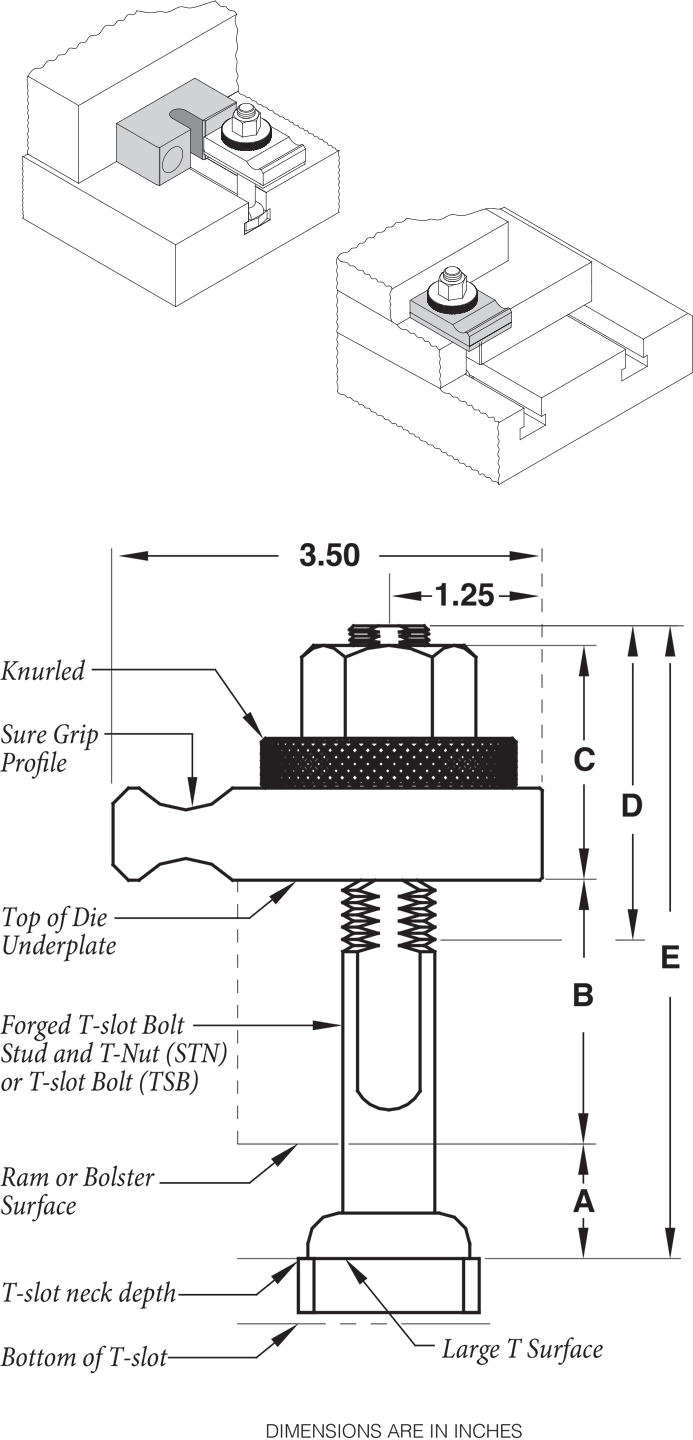

Mechanical Quick Set Clamps

When to Use 1/4 Turn Quick Set Clamps:

Use mechanical quick set clamps with dies having slotted die plates and enough over slot clearance for the set clamp body. U-Slot brackets or ears may also be added to the dies or a heel block added to the back of the clamp for some applications.

How they work:

To use, move clamp into position and manually hand tighten nut using the large diameter knurled surface. Use a wrench to torque to the desired preload. The large bronze alloy nut acts as an easy turning, anti-galling, large surface thrust bearing arrangement for superior performance.

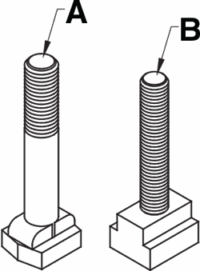

Model 255 clamps require approximately 125 ft.-lbs. of torque to preload the clamp to 10,000 lbs. clamping force. Model 259 clamps require approximately 350 ft.-lbs. to preload clamp to 20,000 lbs. clamping force (unlubricated threads). Clamp preload should be limited to 20,000 lbs. and 40,000 lbs. respectively.

Options and features:

ARA vs. FRA. Free Rotation (FRA) clamps use standard threaded bolts, while Anti-Rotation (ARA) models use modified threads to prevent the clamping plate from spinning about the bolt.

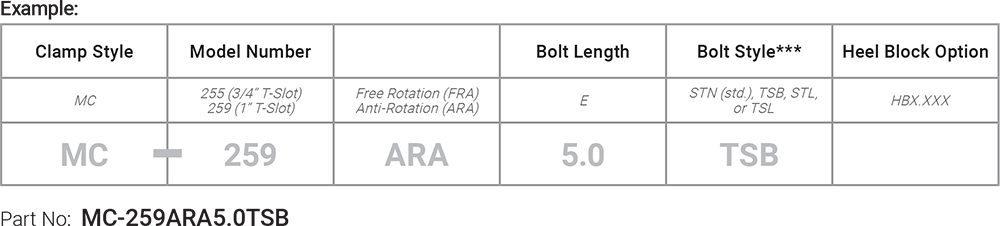

STN or TSB. Stud with attached T-Nut (STN) is standard for a wide range of clamping heights. Forged T-Slot Bolts are also in use for some sizes.

HB Option. In cases where customers desire to use the clamp in applications without slotted die plates, a heel block may be added to the clamp to support the back of the clamp. (Clamping force is 50% of rating.) For this option specify HBX.XX at the end of the part number. (X.XX = clamping plate height in inches.)

Nut Retention Option. In cases where customer desires to prevent the nut from coming off the bolt. A stop mechanism is added to the top of the bolt. Use STL in place of STN (or TSL in place of TSB) in the part number for this option.