Anyone who has experience with robotics in a manufacturing setting likely already knows the importance of end of arm tooling, or EoAT. As a common type of End of Arm Tooling, grippers are used to grasp objects and can be found on assembly or pick-and-place applications; however, the most overlooked part of the entire system is often the gripper pads that are used to protect EoAT applications. But what are gripper pads, and what makes them so essential with robotic end of arm tooling systems?

The Benefits of Gripper Pads for EoAT

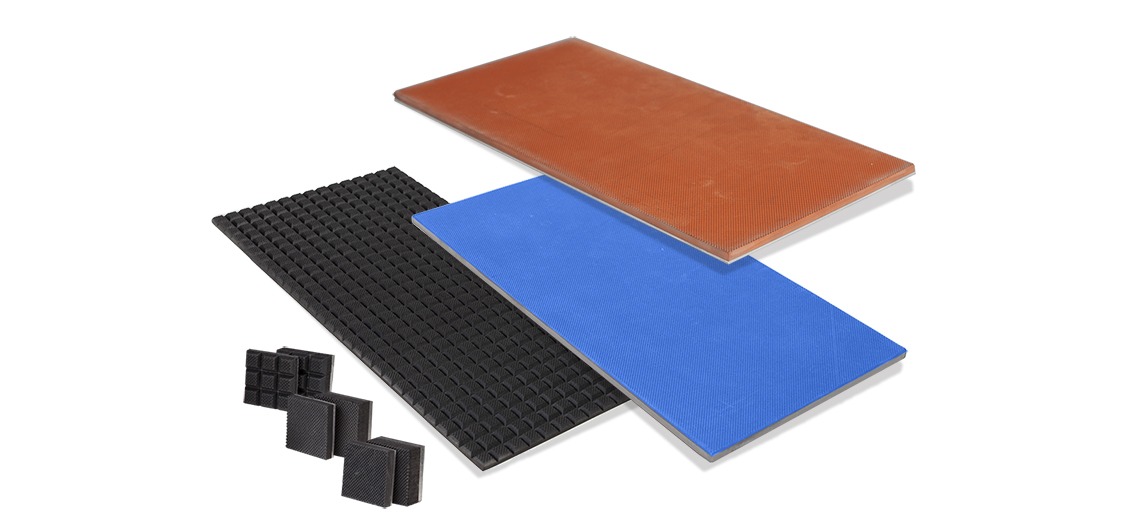

Durable, non-slip gripper pads provide strong gripping surfaces for grasping items using lower clamping forces. At the same time, these products protect parts when handling and assembly are required. These gripper pads are developed with rubber elastomers that operate under various temperature ranges while also resisting common oils or corrosive elements – making it even more beneficial for protecting the end of arm tooling.

In addition to these material choices, metal backings are also installed to provide stiffness while supporting the rubber. Gripper pads with backplates are cure-bonded to aluminum, carbon steel or stainless steel with molecular-level integration to offer an even stronger bond. Metal-backed pads are easily machined to match custom applications, and holes may be drilled to provide quick attachment and removal. Although, the metal backing also allows for easy attachment to gripper jaws or other structures. Some other key features and benefits that can be achieved include:

- High Friction Surface

- Maximum Rubber to Metal Bond

- Improved Reliability for Gripping Parts

- Compliant Surface for a Softer Touch

- Easy Installation and Replacement

- Saves Tooling and Reduces Waste

- High Return on Investment (ROI)

In the past, gripper pads were only available in 6″ or 12″ sheets of three-surface styles bonded to steel or aluminum. PFA customers now have the option to obtain much smaller sheets, typically within 1.2″ x 1.2″ sections, as well as multiple materials and durometers. Additionally, PFA can also offer customers a broad range of special order offerings to meet their unique needs. Unique pad configurations and styles are also available as bulk material or as finished parts from customer-provided drawings or specifications.

One final benefit of gripper pads is their ability to provide 50% – 400% more grip than metal against metal alone. Frictional effects can depend on a range of factors, including part materials, surface finish, and clamping forces applied. A lighter force and rougher finish will often achieve the most grip strength while conforming to a part shape will further enhance performance. PFA rubber gripper pads meet various modern manufacturers’ needs that utilize robotic gripping or focus on pick and place, work holding, or other general industrial applications.

To order PFA Inc.’s rubber gripping pads online, we encourage you to visit the online store product page. No matter what questions you may have, our knowledgeable sales team is here to help. We look forward to helping you ensure your end of arm tooling remains safe and efficient – no matter what application they may be used for.