For the injection molding industry, high production output and low machine downtime is the key to success. Having reliable systems installed into your machines and using cost-efficient materials for your molds will help you accomplish this goal. PFA Inc. has revolutionized the clamping system in injection molding machines (IMM) to work seamlessly with aluminum molds. This clamping system provides many other benefits to injection molding. This article will highlight why the PFA Inc. Hydra-Jaws QMC system will bring just that to your shop.

What Is the Hydra-Jaws QMC System?

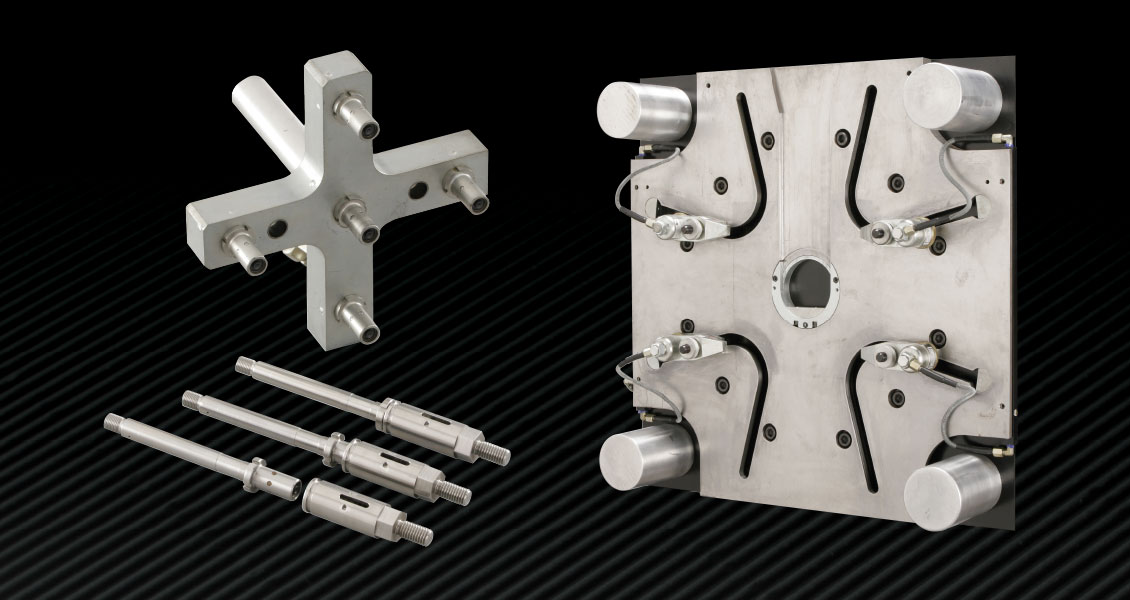

The Hydra-Jaws Quick Mold Change (QMC) System is a locking system that is an alternative to your standard mechanical clamping systems, magnetic clamping, and bolt-through fasteners. This innovative system uses hydraulic pressure applied evenly among all the clamps to secure molds of many different materials. The Hydra-Jaws QMC system works well with non-magnetic materials like aluminum.

The clamps for the Hydra-Jaws are positioned into boomerang-shaped slots, creating a secure fit. Using hydraulic clamps like the Hydra-Jaws allows the operator to control the tonnage being applied to the molds via hydraulic pressure. Once the desired tonnage is reached, the operator can mechanically lock the clamps into position with locking nuts. This means that you can release the hydraulic pressure while maintaining the tonnage. The clamps are positioned into boomerang-shaped slots, creating a secure fit.

Why is the Hydra-Jaws QMC System the Best for Aluminum?

Studies have shown that aluminum is one of the best materials to use for IMM. These studies have demonstrated that using aluminum for your molds provides a less expensive method of producing molds, shortens the mold delivery time, and produces higher-quality molded plastic parts. All of this lets your shop increase parts per day being produced. This obviously equates to more profit within your company. Aluminum is non-magnetic; therefore, any magnetic clamping system would be useless with the material. The Hydra-Jaws QMC System is beneficial with aluminum molds.

How Do I Install the Hydra-Jaws QMC System?

While traditional mechanical clamping systems work with aluminum molds, PFA Inc.’s Hydra-Jaws system is much simpler to integrate and install into your injection molding machines. The Hydra-Jaws utilizes a bolt system that attaches the platen plates directly onto the machine plate. Once the system is bolted in place, all you need to do is attach the side hydraulic manifolds, place the clamps in the slots, and then connect the hoses. This simplification of the installation process increases the efficiency and effectiveness of your shop.

What are the Other Benefits of the Hydra-Jaws QMC System?

SMED (Single Minute Exchange of Die) is made possible throughout your shop with the simplicity of the Hydra-Jaws QMC system’s installation. Time is money in any industry, particularly the molding industry. Keeping your parts per day up is essential for the success and growth of your company. This means downtime must be kept at a minimum. SMED is a significant benefit that the Hydra-Jaws system can give. While SMED is not only possible with the Hydra-Jaws system, but also made easier when paired with it.

While the typical bolt-on platen plates are more commonly used in shops, PFA Inc. will also provide you with various systems that meet your particular needs. This includes multiple-slotted plates, single-side clamping, and in-machine platen slots. This variety is a significant benefit that the Hydra-Jaws QMC system will offer your company.

Time is money, but variety is the spice of life. The two mixed together equates to a company that is sure to sit on top of the molding industry as king. PFA Inc.’s Hydra-Jaws QMC system is just the right thing you need to accomplish this.

Why Choose PFA, Inc.?

PFA manufactures locking cylinders, and core pull cylinders for molds and dies; quick mold change and quick die change systems for injection molding, die casting, and metal stamping; locking and braking actuators/cylinders for work cell and heavy industrial applications; and robotic end-effectors, grippers, and gripper pads for robotic applications. Both off-the-shelf and custom solutions are available to make your application a success. Contact Us | (262) 250-4410