I. Introduction

Locking and braking cylinders are vital components of modern machinery, serving to enhance safety, stability, and efficiency in various industrial applications. As industries evolve and seek to improve their processes, these technologies have also undergone significant advancements. In this blog post, we will explore the latest developments in locking and braking cylinder technologies and how these innovations are reshaping manufacturing practices.

II. Understanding Locking and Braking Cylinders

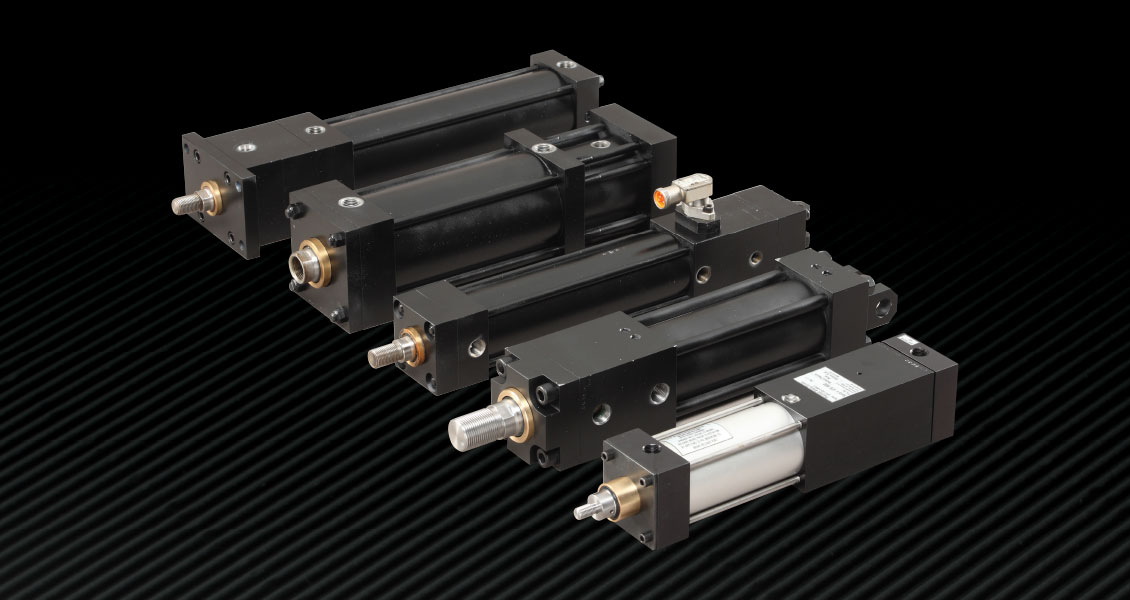

Locking and braking cylinders are mechanisms that control motion in machines, securing parts in place or stopping movement when necessary. Here’s a quick rundown of their purposes:

- Locking Cylinders: These enable the secure holding of loads or parts, preventing unintended movement. They play a crucial role in applications where safety is paramount, such as in mold and die change operations.

- Braking Cylinders: These are designed to slow down or stop moving components, providing a controlled method of halting motion to enhance safety and process reliability.

Importance of Locking and Braking Cylinders:

- Safety: Minimizing the risk of accidents by ensuring components are held securely.

- Stability: Supporting the structural integrity of various machinery.

- Operational Efficiency: Reducing downtime and maintenance costs by providing reliable performance.

By understanding these technologies, manufacturers can appreciate their contribution to overall safety and efficiency in industrial operations.

III. Historical Context: Evolution of Locking and Braking Technologies

To grasp the advancements, let’s take a moment to look at how locking and braking technologies have evolved over the years.

- Early Technologies: Initially, these cylinders were primarily mechanical, utilizing basic lever systems and springs to hold positions. Their reliability and effectiveness were limited by the materials used and the construction techniques available at the time.

- Key Milestones:

- Transition to hydraulic systems in the late 20th century, which significantly improved force exerted by these components.

- Introduction of pneumatic systems that offered improved response times and more significant power density.

- From Mechanical to Modern Systems: Today, we see a shift towards smart technologies and enhanced capabilities, allowing for more versatility in applications.

Understanding this historical backdrop helps highlight the impressive strides made in recent years.

IV. Recent Advancements in Locking and Braking Cylinder Technologies

A. Smart Technologies

One of the most noticeable trends in locking and braking cylinders is the integration of smart technologies.

- Real-Time Monitoring:

- Sensors embedded within locking and braking systems allow for continuous monitoring of performance.

- These devices can provide valuable data on cylinder status, load conditions, and maintenance needs.

- Advantages:

- Early detection of potential failures, reducing downtime and maintenance costs.

- Enhanced safety protocols through automated alerts and controls.

By leveraging smart technologies, businesses can optimize their operations and ensure a higher level of safety.

B. Enhanced Materials and Manufacturing Processes

Material science has also played a pivotal role in advancing locking and braking cylinders.

- Lightweight and High-Strength Materials:

- Development of new alloys and composite materials that are lighter without sacrificing strength.

- Improves energy efficiency and enhances mobility in machinery.

- Innovations in Manufacturing:

- Adoption of 3D printing technologies, enabling customized components with complex geometries.

- Reducing waste and manufacturing time, leading to cost savings.

These advancements contribute to more resilient and efficient systems that can withstand the rigors of industrial applications.

C. Energy Efficiency Improvements

As industries focus on sustainability, energy efficiency has become a key driver in the design of locking and braking systems.

- Energy-Efficient Mechanisms:

- Development of locking and braking systems that consume less energy during operation.

- Utilization of features like regenerative braking, where energy is recaptured during the stopping process.

- Impact on Operational Costs:

- Reduced energy consumption leads to significant savings on operational costs.

- Contributes to a smaller carbon footprint, aligning with sustainable manufacturing goals.

The emphasis on energy efficiency not only benefits the environment but also enhances the bottom line for businesses.

V. Applications and Case Studies

Now that we’ve explored these advancements, let’s look at how they’re applied in real-world scenarios.

A. Automotive Industry

Locking and braking technologies are critical in automotive manufacturing:

- Examples:

- Use of advanced braking cylinders in assembly lines to ensure stability during vehicle construction.

- Integration of locking cylinders in high-volume manufacturing for secure part transitions between stations.

B. Heavy Machinery and Industrial Equipment

- Case Studies:

- A leading construction equipment manufacturer implemented smart locking cylinders, resulting in decreased operational downtime by 25%.

- Another manufacturer adopted lightweight braking cylinders in their machinery, leading to a 15% improvement in fuel efficiency.

C. Aerospace and Defense

- Importance:

- In safety-critical applications like aerospace, advanced locking and braking technologies are essential for ensuring the functionality and reliability of components.

- Organizations in this sector are turning to cutting-edge technologies to enhance safety measures in manufacturing processes and elevate operational standards.

These case studies exemplify how advancements in locking and braking technologies lead to substantial improvements in various industries.

VI. Future Trends and Predictions

Looking ahead, the future of locking and braking cylinder technologies is promising.

- Potential Advancements:

- Further integration of AI to optimize operational efficiency and predictive maintenance.

- Development of more intuitive user interfaces for easier monitoring and control.

- Market Trends:

- Expected growth in demand for smart and energy-efficient solutions as industries increasingly emphasize automation and sustainability.

- The continued evolution of materials and manufacturing processes that support customization and flexibility.

By anticipating these trends, businesses can better prepare for the future of their operations.

VII. Conclusion

Locking and braking cylinder technologies have come a long way, significantly impacting safety, efficiency, and operational reliability across various industries. The recent advancements in smart features, improved materials, and energy efficiency continue to shape manufacturing practices.

For business owners and manufacturers, staying informed about these developments is crucial for leveraging the benefits they bring. As innovative products evolve, the potential for increased productivity and enhanced safety remains vast. Embracing these advancements might just be the step towards a more secure and efficient manufacturing process.

As we conclude our exploration of advancements in locking and braking cylinder technologies, we encourage you to stay engaged and informed. The journey of progress in this sector is ongoing, and who knows what innovations the future may bring!