Tips to Stay Safe When Operating a Hydraulic Press

Hydraulic press machines should be fitted with failsafe locking systems and operators kept informed and engaged with the safety processes.

Hydraulic press machines should be fitted with failsafe locking systems and operators kept informed and engaged with the safety processes.

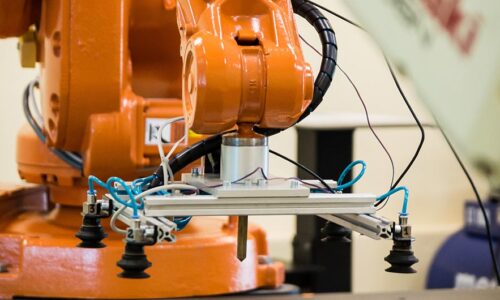

Choosing the best gripper for your environment can be the difference between operational success and failure.

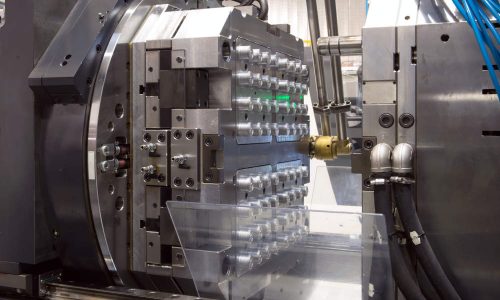

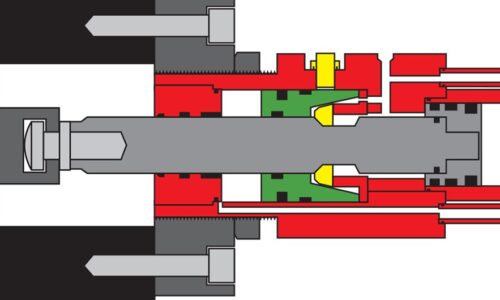

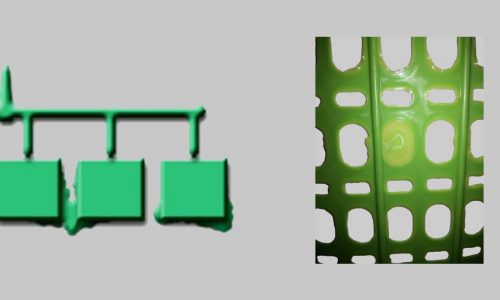

Since many injection molded products have special requirements, a mold side-action or slide is often used to form complex geometries and release the finished product upon mold opening. To achieve this, a “slide” or “slider” is often used as a core-pulling mechanism. At its most basic level, the slider is used to turn the vertical […]

The KOR-LOK® Side Action System sets itself apart from other Hydraulic Core Pull and Locking cylinders by preloading cores to high forces.

Injection molding machines can now be tended around the clock with COBOTS, a cost-effective, easy-to-use solution.

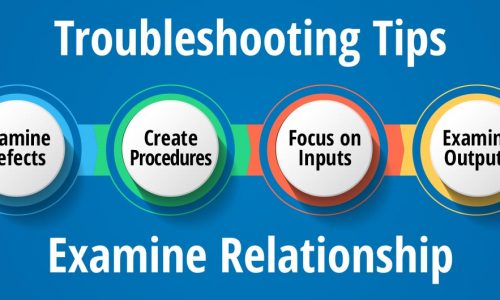

Anyone who has worked with plastic injection molding machinery, likely knows that issues can happen. Unfortunately, when they do, they often result in wasted materials and directly impact the speed and quality of the finished parts that are created. Not all troubleshooting steps are going to work for each application, but knowing what tips are […]

As a common defect in injection molding, flash can have a significant impact on the level of scrap you are producing or cost of secondary processes as a manufacturer. While Automotive and Medical suppliers typically reduce scrap to near zero as part of the controlled process monitoring, many other components do not operate with as […]

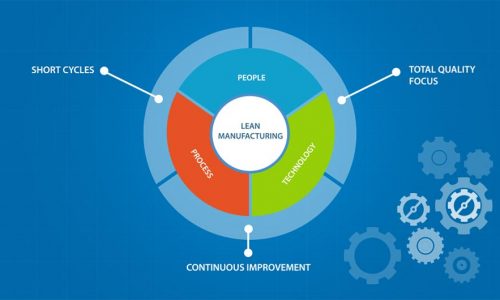

No matter what upcoming projects you may have as an injection mold builder or injection molder, there is a good chance that you are looking for ways to save money – improving your injection molds or molding process. While the steps required to complete a project may be diverse and specific demands targeted to unique […]

While there is no denying that plastic injection molding has positively impacted a variety of different industries, the recent coronavirus pandemic has led many manufacturers to determine how their services may impact the medical industry or other associated industries in times of need. Modern medical-grade plastic injection molding can be used to create medical devices, […]

Injection molding defects are often inevitable, and depending on the type of mold, various things could affect part quality. Typically, challenges are factors like material differences, ambient environmental impacts, machine changes, margins of error, and much more. Simply put, a variety of different things can cause injection molding defects; however, there are also small changes […]