Maintaining or enhancing injection mold profitability is essential for complex applications. For this reason, it is important to utilize a reliable and well-constructed hydraulic locking cylinder or core pull to optimize mold design for success. For injection molders that are ready to improve their mold performance and make their parts as efficient as possible, the PFA KOR-LOK® is the obvious choice. In this article, we will explain the benefits of utilizing the PFA KOR-LOK® for injection mold profitability and some of the ways our hydraulic locking cylinder can enhance your injection molds.

The PFA KOR-LOK surpasses other competitive products because it provides the ability to pre-load cores to achieve high force while at zero PSI. This ensures that your injection mold profitability remains high. Unlike other competitive products that are unable to pre-load cores to high forces, the PFA KOR-LOK® is able to achieve this with relative ease and minor adjustment for a superior injection mold with each application.

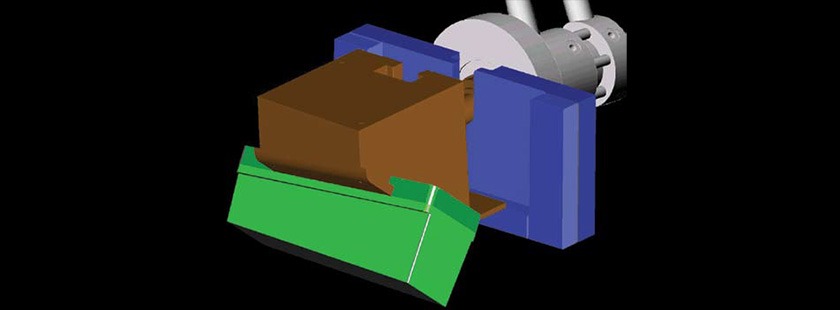

Any time the pressure or temperatures changes during injection, there is a chance that your core face position and core length may change. In addition to core compression and thermal variation, the PFA KOR-LOK® can also be used to compensate for various assembly tolerances that may be present. We created the PFA KOR-LOK® to eliminate these problems by allowing injection molders the ability to ensure the core is pre-loaded above the target injection force. This eliminates all movement at the part interface and does so with a very small cylinder at only 1,500 psi to lock. A small, high speed, high preload cylinder that locks and holds at zero psi, eliminates complex timing requirements, reduces mold size and thus machine size, allows for faster operation and ultimately improves the bottom line.

In addition to the previously mentioned benefits, the PFA KOR-LOK® also provides many other design features that are incorporated to make the product easier to design with and thus increase injection mold profitability. Some of the features include multiple sensor styles, locations and guards as well as a large bore cylinder for enhanced pull force, and peripherals for integration such as plug and play wiring solutions (Switchmax®). At PFA Inc. we know that a hydraulic locking cylinder should work in conjunction with the unique needs of a variety of injection mold processes. We are confident that the PFA KOR-LOK® side action system is the perfect fit your upcoming projects that require the use of a hydraulic locking cylinder to control your mold cores more effectively. Call PFA today for a free application review on your next mold.