Efficiency is a word that is often used in all aspects of business. “Increase efficiency” or “Strive to become more efficient” are goals many companies share, including those in the mold manufacturing profession. Many think of efficiency as lowering the cost of operations and increasing profitability. While it is true that higher profit makes for a more efficient business model, efficiency is all of the little things that go into gaining that profit.

Efficiency is reducing the time it takes to create your products by using newer and more advanced technologies, increasing your employees’ motivation by making a more comfortable workplace, increasing customer satisfaction by offering quality products at competitive prices, and so much more. For companies within the mold manufacturing profession, if they genuinely want to become a more efficient business, then these are some things that they must look at and find strategies to achieve.

This article will try to give you some of the industry’s best strategies for implementing and achieving efficiency for your company.

Time = Money

Time is money, and that is just a fact. The more time you spend setting up and tearing down, the fewer products you can create for your customers. In turn, the longer it takes for your operations to get the products to the buyer, the lower customer satisfaction will become. By changing one variable here, you will increase efficiency in profits and also customer satisfaction.

That variable is time.

The faster you can change molds and equipment, the more products you can create. Then this is a snowball effect as customers get their products faster, are happier, are more likely to come back for more, and increase their profit margins.

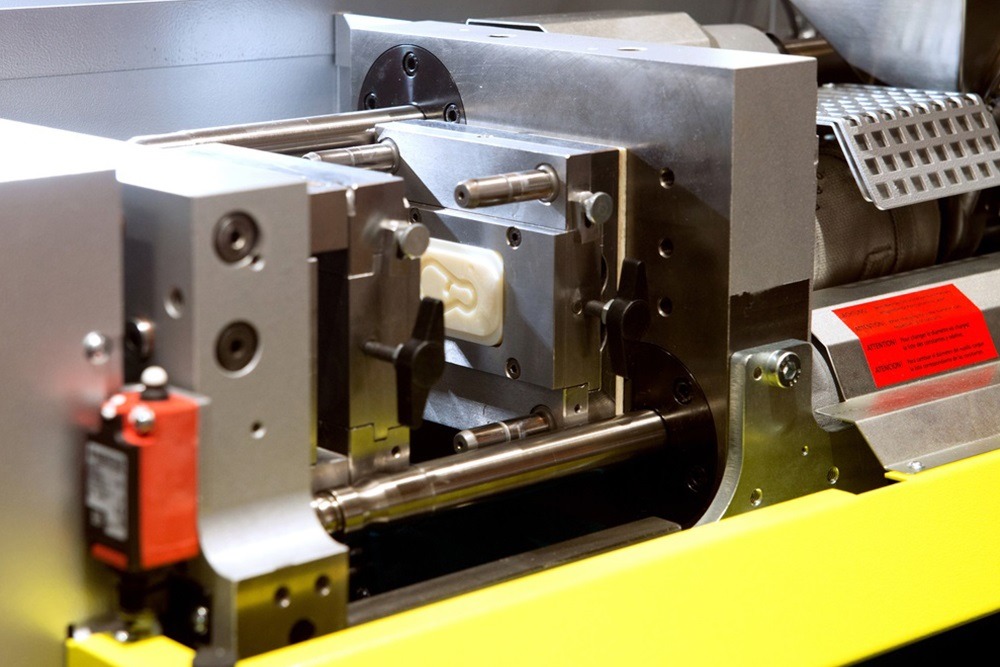

Keeping up to date on your technology is essential for reducing time. Thirty years ago, the best machines you could buy were tedious and time-consuming to change and operate. Then came CNC machines to save the day, but they still took too much time to change and set up. New advances in five-axis machine tools are changing the game in terms of time.

These five-axis machines have a much-simplified setup process. This means you can spend more time machining your molds than ensuring the alignment and calibrations are correct. Obviously, there are many factors that you need to consider when finding the best five-axis machine for your company.

The size of molds needed to mill, the size of your workspace, and the cost are a few of the main factors. However, there are many great companies out there to offer you the best machines you could ask for. PFA, Inc can help you find suitable five-axis machines for your company.

The machining process is not the only technological advancement your company needs, though. Advancements in ERP, simulation software, CMM machines, and robotics are sure ways to make your operations timelier. With new technologies come new expenses. It will be an investment to keep up to date with all the technological advancements in the mold manufacturing industry. However, if you want your company to be efficient, then it is an investment you must be ready to make.

Employee-Centered Culture

The machines and technology are not enough to make your company the best. Your employees will be responsible for running and managing your top-of-the-line equipment, whether you house a few or many. So, it only follows that if they are not loyal, motivated, and competent employees, then your operations will not be as efficient as you need them to be.

Creating an employee-centered culture is vital in all companies. There are many ways to accomplish this in the mold manufacturing industry. Try letting your employees in on the mold-designing process. This will give them a sense of involvement and ownership with the products they are helping you create.

Weekly or monthly conferences to discuss new jobs, new processes, or new equipment will keep them in the loop. This is also an excellent time to ask for feedback on anything they do. Some companies even go as far as to walk their employees through the income statements for the period during these meetings. This lets the company be entirely transparent with its employees. Pair these conferences with walk-throughs; you will help build an environment that lets your employees feel loved and appreciated.

Having an employee-centered workplace will drastically improve your efficiency. It will give your employees a sense of purpose and a sense of ownership, making them work harder to complete tasks on time. Not to mention a happy employee is less likely to seek out other employment. This will cut down on your training expenses.

Creating Repeat Buyers

The goal your company should have is to make sure that customers will return to give you more money. Not only is this good for your bottom dollar, but it is also good for morale. If a customer returns with more orders, they are pleased with the product or service you gave them. This tells you, your employers, and your investors that your business model is working and is efficient.

You should spend a reasonable amount of time trying to keep customer satisfaction at the highest level possible. This is a snowball effect, though. Investing in the best equipment will give you the best quality product. If you have the best quality product, your employees feel more accomplished and work harder to meet order deadlines. And this goes on and on until you finally have a delighted customer. This customer shows off their products to friends, and not only do they come back for more, but they also have friends coming with them.

Possibly the most crucial metric that displays efficiency is profit. If profit is low, you are not operating very efficiently, and things need to be changed. If profit is high, then your company is doing everything they need to do to be efficient. There is a lot that goes into that high profit. This article, hopefully, has enlightened you on what you can do to make your company more efficient.

However, profit can always be higher, employees can always work harder, and your operations can always be more efficient. PFA, Inc can help you evaluate your operations and determine the best route to make your business the most efficient in the industry.

Why Choose PFA, Inc.?

No matter what a manufacturer’s needs may be, PFA, Inc. is sure to have the right products to help. For more information about how our products improve your plastic injection molding processes, visit our products page. For more immediate assistance, reach out at our contact us page or call us now at (262) 250-4410!