Did you know that nearly 2.8 million workplace injuries and illnesses are reported by private industry employers annually? Positive hydraulic locking systems and actuators are essential for maintaining productivity and safety standards among modern manufacturers. These systems may not always provide the support needed to eliminate flash and produce the best products possible. This article will look at how hydraulic actuators work and explain some of the benefits associated with the KOR-LOK Side Action Systems from PFA, Inc.

Hydraulic actuators are a cylinder or fluid motor that relies on hydraulic power to control or move mechanical systems through rotary or linear motion. As you might imagine, this required directional control signals from a value and a hydraulic energy source. My hydraulic actuators rely on fluid pressure because it is highly non-compressible and can be transmitted instantly to adjust torque or hold forces without the need for more pressure. This makes a hydraulic actuator critical when large forces or high speeds are required.

Hydraulic actuation is often the standard for motion control in injection molding applications; however, many manufacturers are starting to invest in electric actuation to achieve greater speeds. Many improvements have been made in modern seal technology to help ensure leak-free use of hydraulic machines. Unfortunately, these methods of maintaining a core preload may not be efficient enough for some applications because of the core preload that is required to complete a part. This is where the PFA KOR-LOK® Side Action System shines.

What is KOR-LOK®?

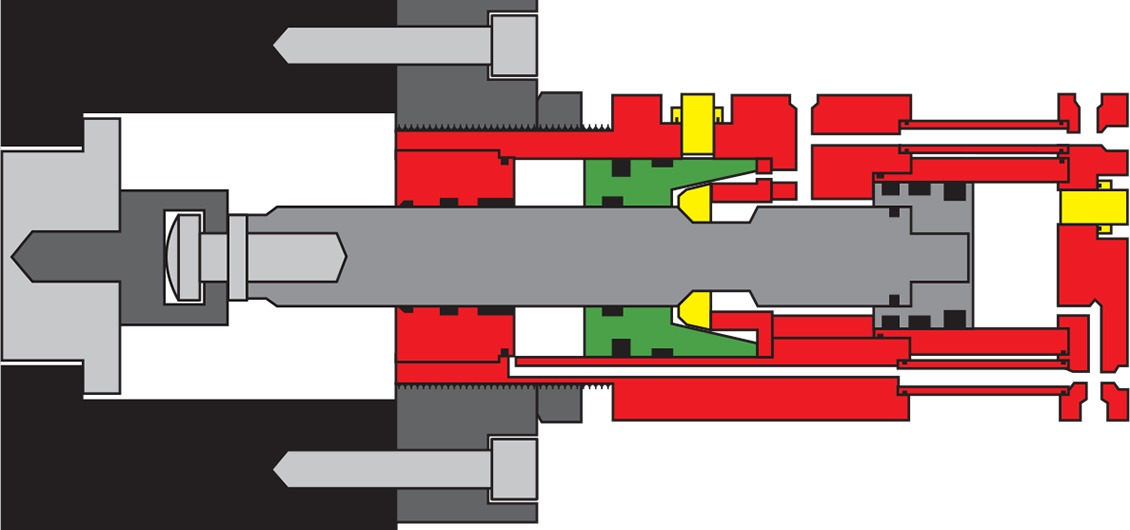

As more than just a locking cylinder, the PFA KOR-LOK® Side Action System sets itself apart from other Hydraulic Core Pull and Locking cylinders by having the ability to preload cores to high forces. At PFA, we feel understanding core forces under injection, understanding the required preload necessary to overcome those forces, and knowing the operation of possible solutions, are critical to choosing the correct “locking” cylinder. As an innovative hydraulic locking core pull cylinder, KOR-LOK® is recommended for all injection molding and die casting applications – regardless of how the action pulls (parting line, side-action, angled, wedge, etc.).

Core preload means your parts can be made quickly with tighter tolerances, perfect match lines and clean, beautiful textures. The all-in-one system means cores can move at any angle at any time, eliminating barriers to many complex parts while also ensuring accuracy at every step by eliminating defects or wasted materials. Specify PFA for design freedom. Indulge yourself. For injection molding applications, KOR-LOK® helps you run the best parts possible in the smallest press possible.

For more information on possible applications for the KOR-LOK® Side-Action System or to obtain more product information, we encourage you to visit the product page below. If you still have questions, we would be happy to explain how this unique hydraulic locking core pull cylinder can enhance your process and provide a free application review. To get started, please contact us, and our friendly and knowledgeable staff will happily assist you.