From food production and cleanroom environments to distribution centers, robotic grippers are the most common End of Arm Tooling (EOATs) in virtually every industry. With various types, sizes, and configurations, there are technical factors that must be considered when choosing the right robotic gripper for your application.

Consider the type of gripper you need.

Vacuum Grippers

Vacuum grippers lift, hold, and move objects using the difference between atmospheric pressure and a vacuum. The vacuum, or flow, is created by either an electromechanical pump or a compressed air-driven pump. Though vacuum grippers can be utilized in a wide variety of tasks, the two more common applications are palletizing and packaging.

While vacuum grippers offer the ability to handle several items at a lower price than other gripper types, they do incur added electricity costs to power vacuum pumps or compressed air. Additionally, they are sensitive to dusty conditions.

Pneumatic Grippers

Using compressed air and pistons, a pneumatic gripper operates its ‘fingers,’ or ‘jaws.’ Pneumatic grippers are versatile tools used in a range of applications and are commonly found in 2- and 3-finger configurations.

Pneumatic grippers come with several advantages, including a low cost, a large grip force, fast response times, and the ability to operate in tight spaces. They are ideal for handling single part types, so keep in mind that they might not be an excellent fit for a facility that produces a lot of low volume, high mix items.

Hydraulic Grippers

With more gripping power than their pneumatic counterparts, hydraulic grippers are ideal for heavy-duty applications. Powered by hydraulic fluids, hydraulic grippers offer supreme gripping power. Hydraulic grippers have several drawbacks despite this gripping power, such as the complexity of handling oil, a pump, and a reservoir. They are higher maintenance than other grippers and not suitable for cleanrooms or most medical applications.

Electric Grippers

Popular for applications with machine tending and pick and place, electric grippers use microprocessors to vary gripping force and speed. Electric grippers generally come in two- and three-jaw configurations, with three-jaw grippers ideal for handling round or cylindrical objects.

Although electric grippers do not wield the same level of gripping power as hydraulic grippers, they are fitting for applications requiring high speed and light, moderate gripping force. Their defining feature is control: their varying grip force means they can easily handle different part types. This finesse comes with less gripping force than pneumatic grippers, as well as a higher cost.

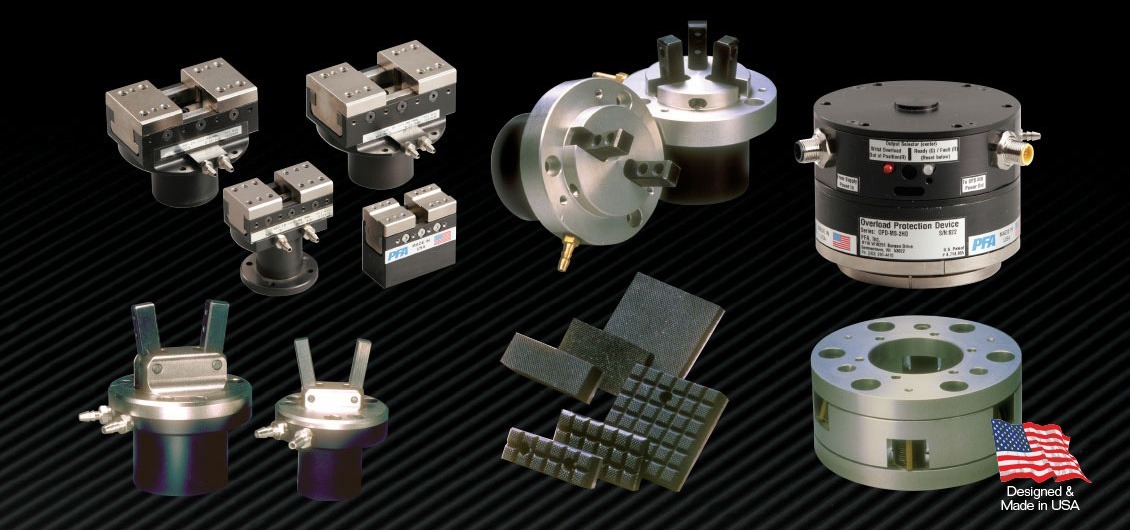

Why choose PFA for your Automation Solutions?

If your robot tooling needs to be able to pick up, manipulate, and place products, you will need a robotic gripper. With so many types, sizes, and configurations on the market, it can be daunting when selecting the optimum gripper for your robot tool. PFA’s team works to determine the best robotic gripper for your application, design, and most importantly, your part or product. Let us help you get a grip on your automation system by contacting us today or calling 262-250-4410.