PFA Inc. provides a complete cylinder pre-loading and locking system for die casters and injection molders. Our goal is to help cavity filling businesses nationwide lock in their manufacturing with both customized and off-the-shelf solutions to assist in high quality part production and rapid tooling changeovers with the confidence that comes with our unique products. In this article, we will look at some of the ways the hydraulic locking cylinders from PFA, Inc. can help you lock in your manufacturing success.

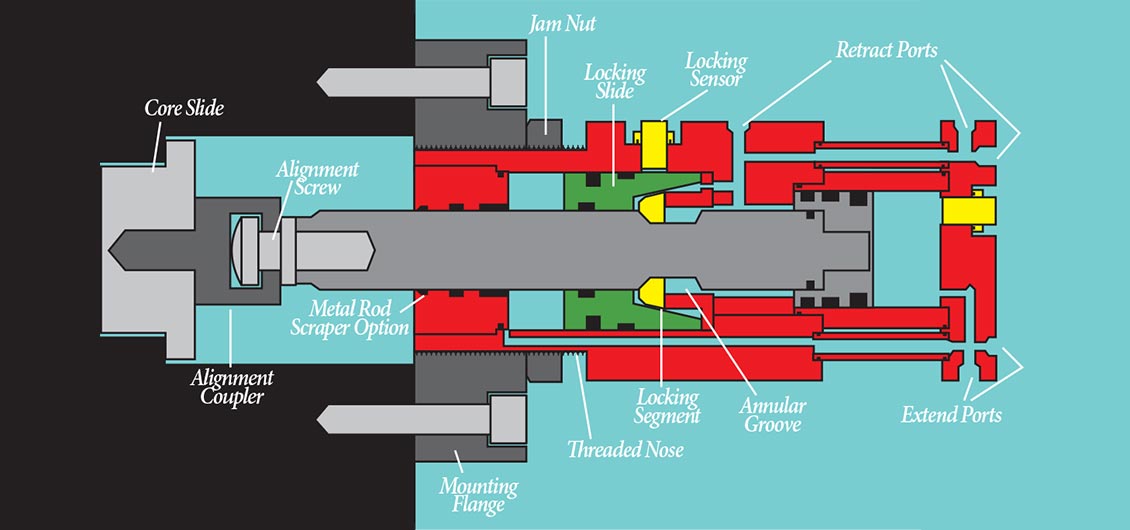

Unlike other products currently available on the market known generically as Hydraulic Locking Cylinders or Locking Core Pull Cylinders, the PFA KOR-LOK™ Side Action System sets itself apart simply by its ability to preload cores to high forces and lock that load in at 0 psi. Many traditional spring-locking, hydraulic-activated solutions and others either do not lock, do not preload, or do not maintain force with loss of pressure, such as during injection. While PFA makes other locking cylinders for general industrial use, only the KOR-LOK® achieves high force preload and cylinder locking to fully rated load a 0 psi in a simple to install system.

Without the KOR-LOK™ Side Action System, pressure and temperature changes will often cause the core face position to “back up” or flex, ultimately changing the desired position and resultant part geometry. Unfortunately, preload and core position problems are directly translated to the end product even if your core was in the correct position before injection. The ultimate goal of the KOR-LOK™ Side Action System is to eliminate these problems by helping you lock in a pre-load force above injection pressure that is maintained at 0 PSI.

Attempting to compensate for compression and thermal effects with tryouts and “tweaking” can become time intensive, repetitive and very costly. Instead of spending precious resources and time chasing the problem, we encourage you to learn more about the KOR-LOK™ Side Action System, to see if it can help improve your mold assembly, tryout, and molding production performance. We are confident you won’t find a better self-locking cylinder on the market and would love to help reduce your mold sizes, run parts in smaller presses, and achieve improved part quality.

For more information on the KOR-LOK™ Side Action System, we encourage you to visit the product page. Here you will find answers to common questions we receive as well as the product specifications and applications for which it is most suited. If you have any questions, don’t hesitate to reach out to us. We would love to hear from you!