Compliance Devices

Compliance Devices

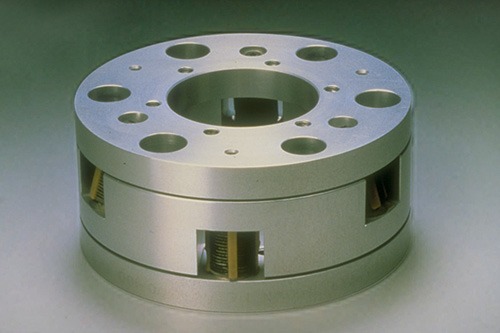

Two-Stage RCC Accommodator

Provides critical force axis de-coupling to reduce part stress during assembly

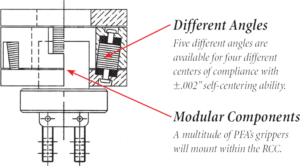

Lateral and Rotational Compensation – Because of the two stage configuration, the part being inserted can comply laterally and rotate around the center of compliance reducing wear of machinery and the need for highly accurate robots.

Automatic Compensation – RCC compensates for positioning errors in automated assembly, thus minimizing the required assembly forces and the possibility of parts jamming.

Variable Durometer Elastomers – Six elastomeric shear pads make RCC’s stiff in compression yet relatively soft in shear ensuring more accurate side to side accommodation. Choose from four different shear pad types to achieve the best compliance for your application.

The Importance of the Remote Center of Compliance (RCC)

The critical aspect of PFA’s RCC is the true de-coupling of the lateral, shear, and rotational forces. The point of de-coupling occurs at a remote point called the Remote Center of Compliance (RCC). Although other compliant devices are flexible, PFA’s Accommodator provides the critical de-coupling effect necessary for critical assembly applications.

Stiffness

The RCC design allows for a trade-off between the lateral and rotational stiffness values for a given projection distance and shear pad type. The units listed have been chosen to balance these two parameters. Stiffness selection should be based on tightness of fit, payload and operating speed. Units optimized for minimum rotation and torque transmission are also available in the anti-rotation (AR) option.

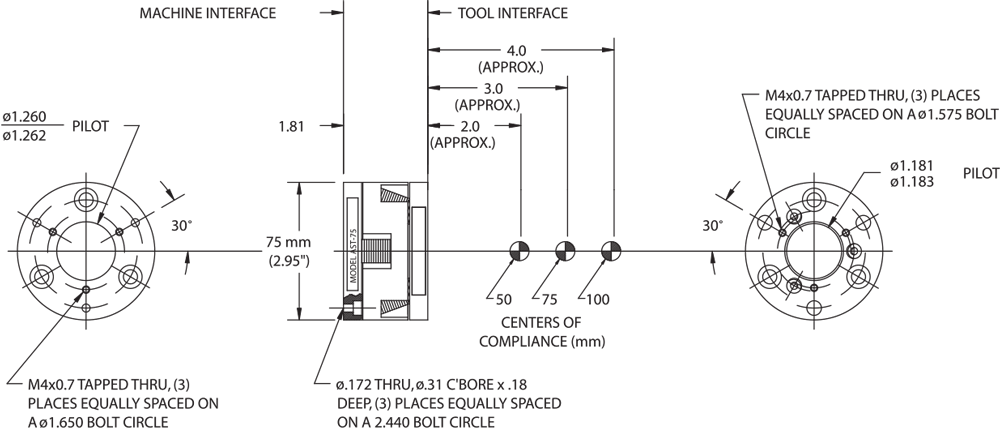

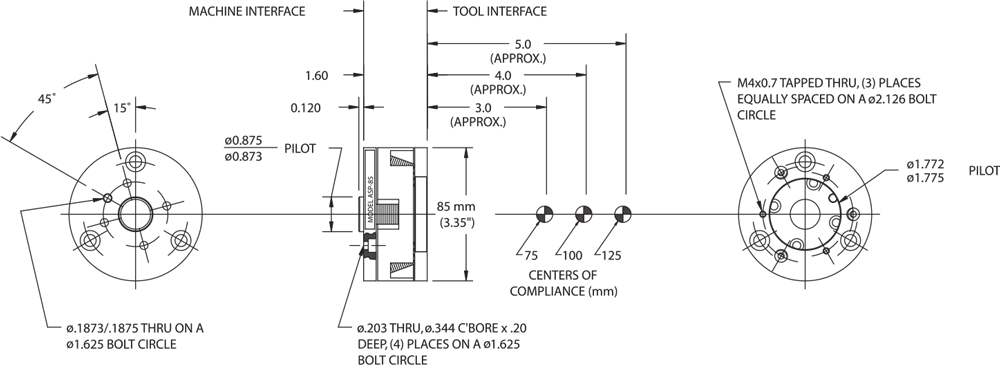

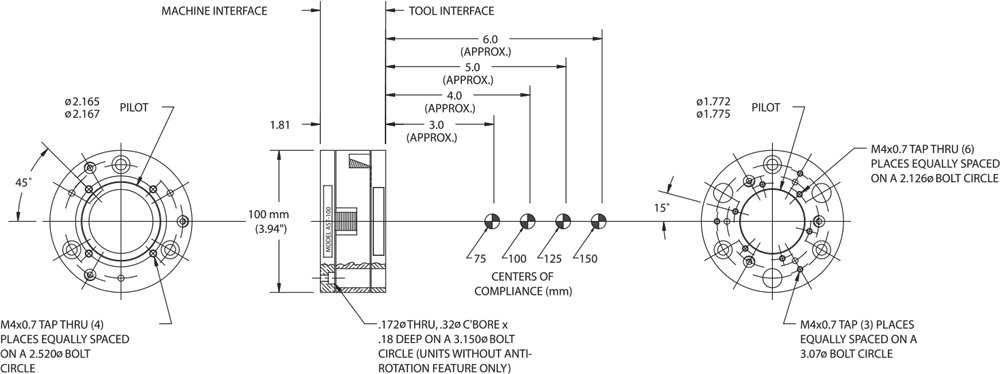

Mechanical Outline Specifications

Shear Pad (Elastomer) Selection

| Properties | CR Neoprene | MO Silicone |

|---|---|---|

| Operating Temperature (Min.) | -29˚C (-20˚F) |

-54˚C (-65˚F) |

| Operating Temperature (Max.) | +82˚C (+180˚F) |

+177˚C (+350˚F) |

| Mechanical Properties | Good | Good |

| Oil Resistance | Good | Fair |

| Ozone Resistance | Good | Excellent |

| Resistance to Heat Aging | Good | Excellent |

| Compound Color | Black | Red |

| Durometer Shore A ± 5 |

35-Red Stripe 45-Green Stripe 55-Blue Stripe |

30 |

Accessories/Options

Cleanroom Capability – Cleanroom class 100 is available for contamination free assembly processes as part of PFA’s modular cleanroom line. Contact PFA for details.

Adaptor Plates – Blank adaptors that mate with the RCC pilot and bolt circle are available for both the machine and tooling interfaces. They are center-drilled so that the customer may adapt the unit to any mounting surface.

Shear Pads – Elastomer Shear Pads are available separately for a variety of custom compliance applications, simply ordered by name. (Example: CR35 Shear Pad)

Model AST-75 Specifications

| Center-of- Compliance Projection mm (in) |

Shear Pad Type MO-30 |

Shear Pad Type CR-35 |

Shear Pad Type CR-45 |

Shear Pad Type CR-55 |

|

|---|---|---|---|---|---|

| Lateral stiffness N/mm (lb/in) |

50 (2.0) 75 (3.0) 100 (3.9) |

12.3 (70) 12.3 (70) 10.5 (60) |

21.1 (120) 21.1 (120) 18.0 (103) |

34.7 (197) 34.7 (197) 29.6 (169) |

49.2 (280) 49.2 (280) 42.0 (240) |

| Rotational stiffness N-mm/mrad |

50 (2.0) 75 (3.0) 100 (3.9) |

49 (436) 90 (797) 169 (1500) |

84 (749) 155 (1370) 290 (2580) |

139 (1230) 254 (2250) 477 (4230) |

197 (1740) 360 (3190) 676 (6000) |

| Axial stiffness N/mm (lb/in) |

705 (4020) | 1210 (6910) | 1990 (11340) | 2820 (16080) | |

| Torsional stiffness N-mm/mrac in-lb/rad) |

4.5 (40) | 7.7 (68) | 12.7 (112) | 18.0 (159) | |

| Axial load (max usable) N (lb) |

1200 (275) | 2000 (450) | 3400 (775) | 4900 (1100) | |

| Weight 0.40 kg (0.87 lb) Lateral travel ±2.5 mm (0.100 in) Rotational travel ±17 mrad (1.0 deg) Self-centering repeatability ±0.05 (0.002) Structure material is anodized aluminum |

|||||

Model ASP-85 Specifications

| Center-of- Compliance Projection mm (in) |

Shear Pad Type MO-30 |

Shear Pad Type CR-35 |

Shear Pad Type CR-45 |

Shear Pad Type CR-55 |

|

|---|---|---|---|---|---|

| Lateral stiffness N/mm (lb/in) |

75 (3.0) 100 (3.9) 125 (4.9) |

12.2 (70) 13.6 (78) 10.5 (60) |

21.1 (120) 23.4 (134) 18.0 (103) |

34.4 (197) 38.4 (220) 29.6 (169) |

48.8 (280) 54.4 (312) 42.0 (240) |

| Rotational stiffness N-mm/mrad |

75 (3.0) 100 (3.9) 125 (4.9) |

86 (766) 130 (1140) 233 (2060) |

148 (1320) 223 (1960) 400 (3540) |

243 (2160) 367 (3220) 657 (5810) |

344 (3060) 520 (4560) 932 (8240) |

| Axial stiffness N/mm (lb/in) |

720 (4080) | 1240 (7020) | 2030 (11500) | 2880 (16300) | |

| Torsional stiffness N-mm/mrac in-lb/rad) |

5.8 (55) | 9.9 (94) | 16.3 (154) | 23.1 (218) | |

| Axial load (max usable) N (lb) |

1600 (350) | 2700 (600) | 4400 (1000) | 6400 (1400) | |

| Weight 0.40 kg (0.81 lb) Lateral travel ±2.5 mm (0.100 in) Rotational travel ±17 mrad (1.0 deg) Self-centering repeatability ±0.05 (0.002) Structure material is anodized aluminum |

|||||

Model AST-100 Specifications

| Center-of- Compliance Projection mm (in) |

Shear Pad Type MO-30 |

Shear Pad Type CR-35 |

Shear Pad Type CR-45 |

Shear Pad Type CR-55 |

|

|---|---|---|---|---|---|

| Lateral stiffness N/mm (lb/in) |

75 (3.0) 100 (3.9) 125 (4.9) 150 (5.9) |

14.9 (85) 14.9 (85) 16.9 (97) 10.5 (60) |

25.6 (147) 25.6 (147) 29.0 (166) 18.0 (103) |

42.0 (241) 42.0 (241) 47.7 (272) 29.6 (169) |

59.6 (341) 59.6 (341) 67.6 (386) 42.0 (240) |

| Rotational stiffness N-mm/mrad |

75 (3.0) 100 (3.9) 125 (4.9) 150 (5.9) |

81 (720) 128 (1130) 175 (1550) 338 (2990) |

140 (1240) 220 (1940) 301 (2660) 581 (5140) |

230 (2030) 361 (3190) 494 (4370) 953 (8430) |

326 (2880) 512 (4220) 700 (6200) 1350 (11960) |

| Axial stiffness N/mm (lb/in) |

670 (3800) | 1140 (6530) | 1800 (10720) | 2660 (15200) | |

| Torsional stiffness N-mm/mrac in-lb/rad) |

8.8 (78) | 15.2 (135) | 25.0 (221) | 35.4 (313) | |

| Axial load (max usable) N (lb) |

2200 (500) | 3700 (850) | 6200 (1400) | 8800 (2000) | |

| Weight 0.60 kg (1.30 lb) Lateral travel ±2.5 mm (0.100 in) Rotational travel ±17 mrad (1.0 deg) Self-centering repeatability ±0.05 (0.002) Structure material is anodized aluminum |

|||||

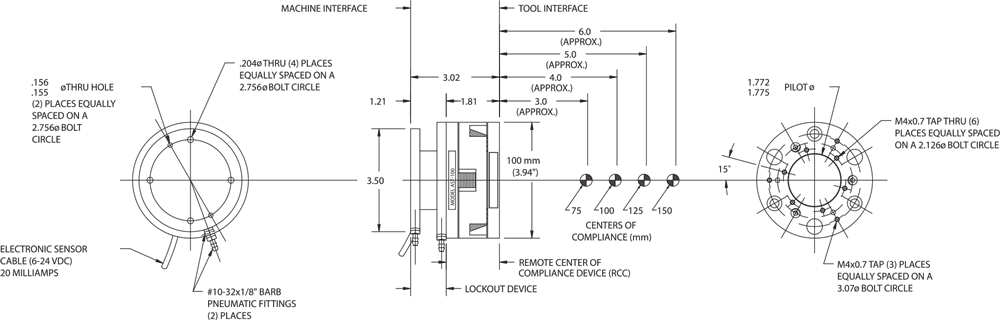

NOTE: DIMENSIONS ARE IN INCHES EXCEPT WHERE NOTED.

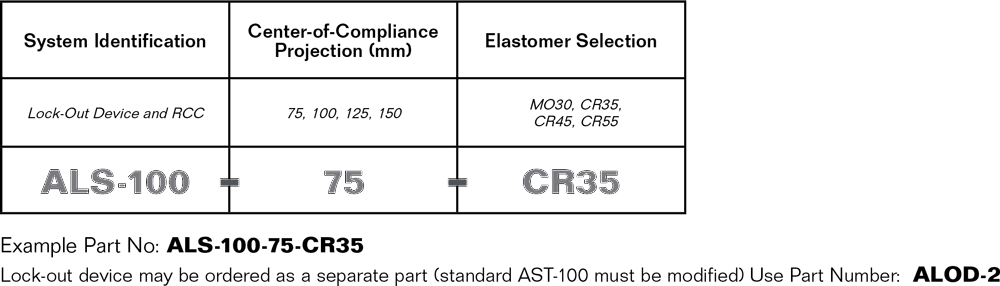

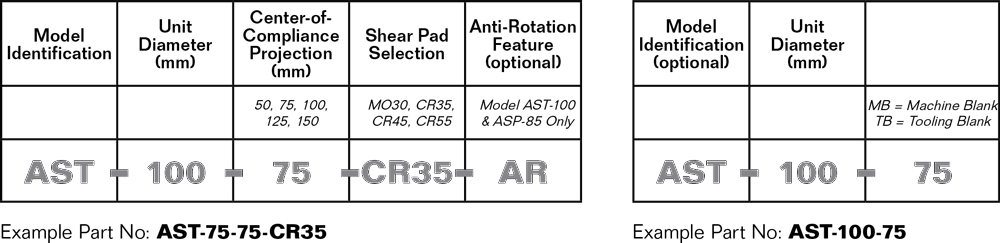

Identify Your Part Number

For elimination of “setting time” in high speed applications, see PFA’s Lock-Out System.

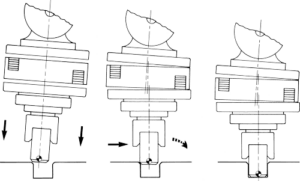

RCC Accommodator with Lock-Out System

Increased productivity of RCC Accommodator with Reduced Cycle Times

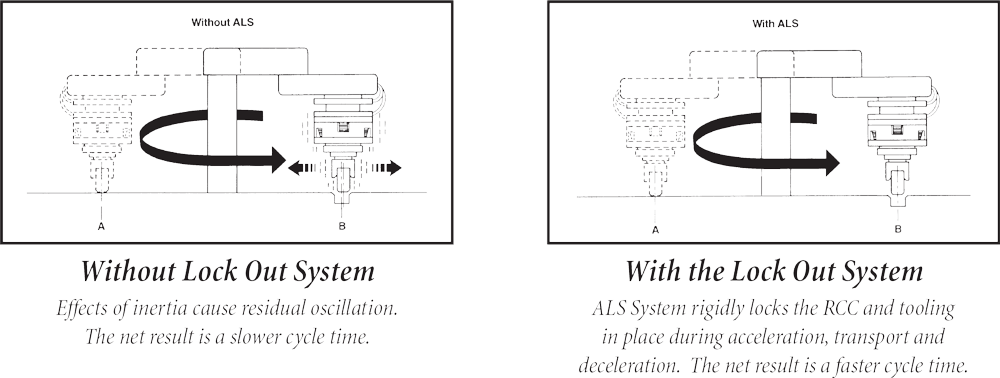

The Lock-Out/RCC System (ALS) has been developed to alleviate the effects of inertia and solve operational problems, such as the need for shorter cycle times, for automated assembly tasks. The system consists of a lock-out device and the incomparable Accommodator RCC. The lock-out device is pneumatically activated and electronically sensed as it locks the X, Y, and Z planes of the RCC on command.

The lock-out device is locked during movement and unlocked immediately before part insertion to allow the RCC to compensate for misalignment during assembly.

Features

- Reduces cycle times

- Permits rapid accelerations/decelerations

- Integrates with modified AST-100 Accommodator RCC’s

- Prevents X, Y, Z, and rotational travel during transition

- Allows a high degree of repeatability

Mechanical Specifications

Mechanical

| Locked Repeatability (at center of RCC) | X, Y, Z axis ± 0.03mm (±0.001 in.), rotationally ± 30’ |

| Unlocked Repeatability (at center of RCC) | X, Y, Z axis ± 0.05mm (0.002 in.), rotationally ± 17’ |

| Operating Pressure | 350 – 800 KPA (50 – 120 PSI) |

| Weight (ALS) | 0.95kg (2.1 lbs) |

| Weight (ALOD-2) | 0.34kg (0.75 lbs) |

| Material | Lock-out device – Teflon impregnated hardcoat aluminum. RCC Accommodator – Anodized aluminum |

Caution: failure to observe supply voltage and output current limits may lead to sensor failure!

Electronic

| Supply voltage (operation) | 4.5 – 24VDC |

| Supply current (max) | 14mA |

| Interconnect cable | 3 conductor, 24 AWG, with shield 48 in. (122mm) long |

| Output configuration | 24VDC; open collector (current sinking) 25 mA max. |

| Output switching time (max) | .04 microseconds |

| Cable connections | red – +DC black – ground white – output |

Identify Your Part Number