When to Use Pneumatic Die Lifters:

Use pneumatic die lifters for lighter dies in small to medium presses. Load capacity is approximately 1/2 of a hydraulic rail for inline cylindrical rollers and similar in lift force for the multi-directional ball rollers, but slot size can be much smaller and overall cost much lower. In many applications, performance is astounding. Fitting in slots as small as 1.250” total depth, very large lift capacities are produced with readily available 85 psi shop air. 1,800 lbf/ft/pair for narrow rails and 2,600 lbf/ft/ pair for wide rails. Temperature rating is 150˚ F (65˚ C). Using shop Air eliminates the need for hydraulics and the associated complexities of adding hydraulic systems to the press.

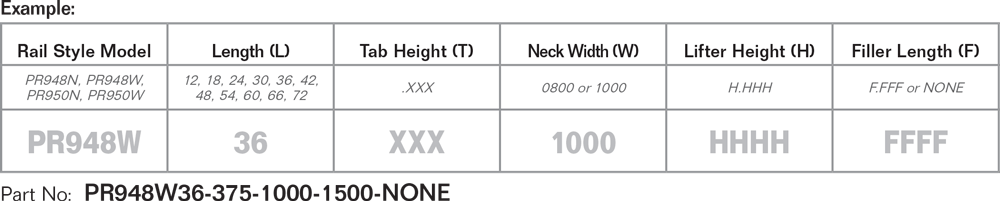

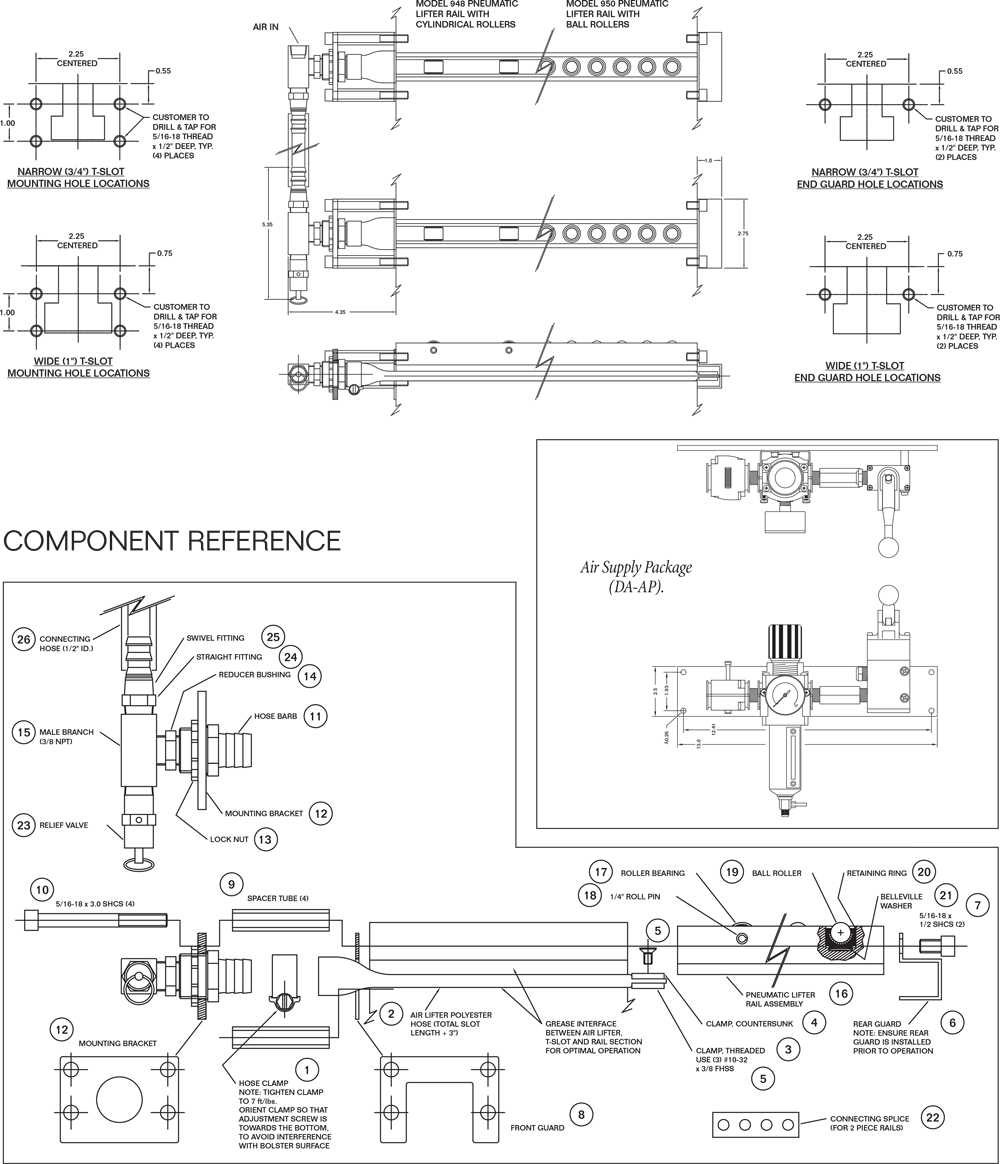

Simple hand operated air valves (or electrically operated valves integrated with other press controls) can be used to actuate the lifters. For an available off the shelf air interface that connects to shop air and provides a Manual Hand Valve, Filter Regulator, and Lockout system, please see information PFA’s Air Package (DA-AP). Designed for standard ¾” and 1” T slots and available to accommodate any press bolster depth, PFA Pneumatic Die Lifters provide a low cost, easy to order, and simple to install option to be used in standalone or integrated applications. Simply add clamps and bolster extensions for a complete QDC system.

How They are Used:

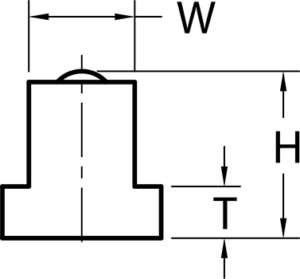

Pneumatic Lifting bars with installed rollers are inserted into the T slots and captured between the separate air lift system installed on the front of the press and the guard attached to the back side of the T slot. The air lift bag or hose occupies the space under the rail in the wider slot section providing the lift force when pressurized. If the rail is sized shorter than the slot, a filler bar is added to maintain rail position in the slot. Rails are made to specific dimensions to match the T-slot and achieve the desired lifting height.

Air rail lifting height is specified by the customer to match the insertion height of other components, such as bolster extensions. Activating with 85 psi air, places the lifter “up” ready to receive the die. The die is loaded with the weight transferring from the bolster extensions to the lifters. Once the die is in the press, the lifters are lowered by closing the supply pressure and venting the lines (typically the valve both secures and vents the line).

Systems are provided with rails, guards, the pneumatic fittings, and hose to connect them together along with a relief valve. Customers provide any desired control valves for air and connect to an NPT port or may purchase an “Air Package” consisting of Lockout, Manual Valve, and Filter Regulator for easy integration.

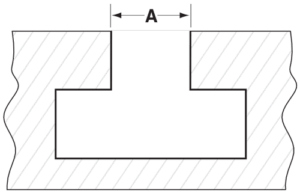

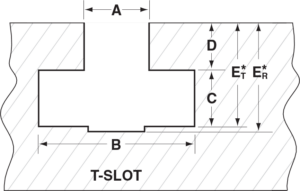

2. Measure T-Slot or Rectangular channel throat.

2. Measure T-Slot or Rectangular channel throat. 1. Measure Neck Height (D), Full Width Depth (ET) and B:

1. Measure Neck Height (D), Full Width Depth (ET) and B: