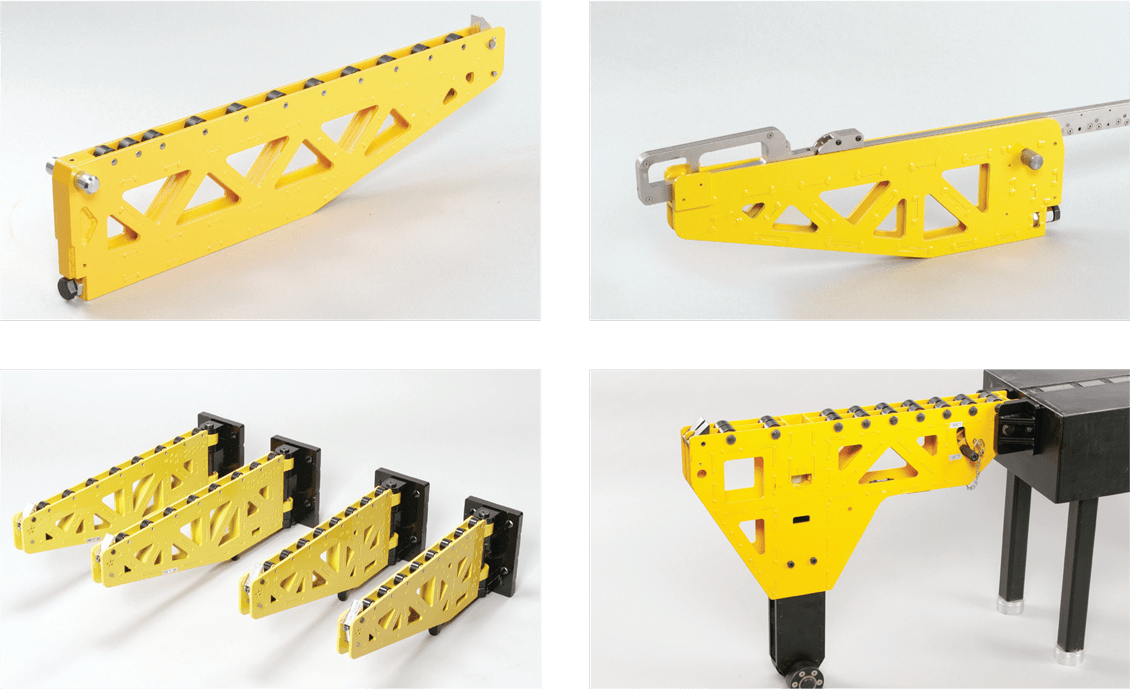

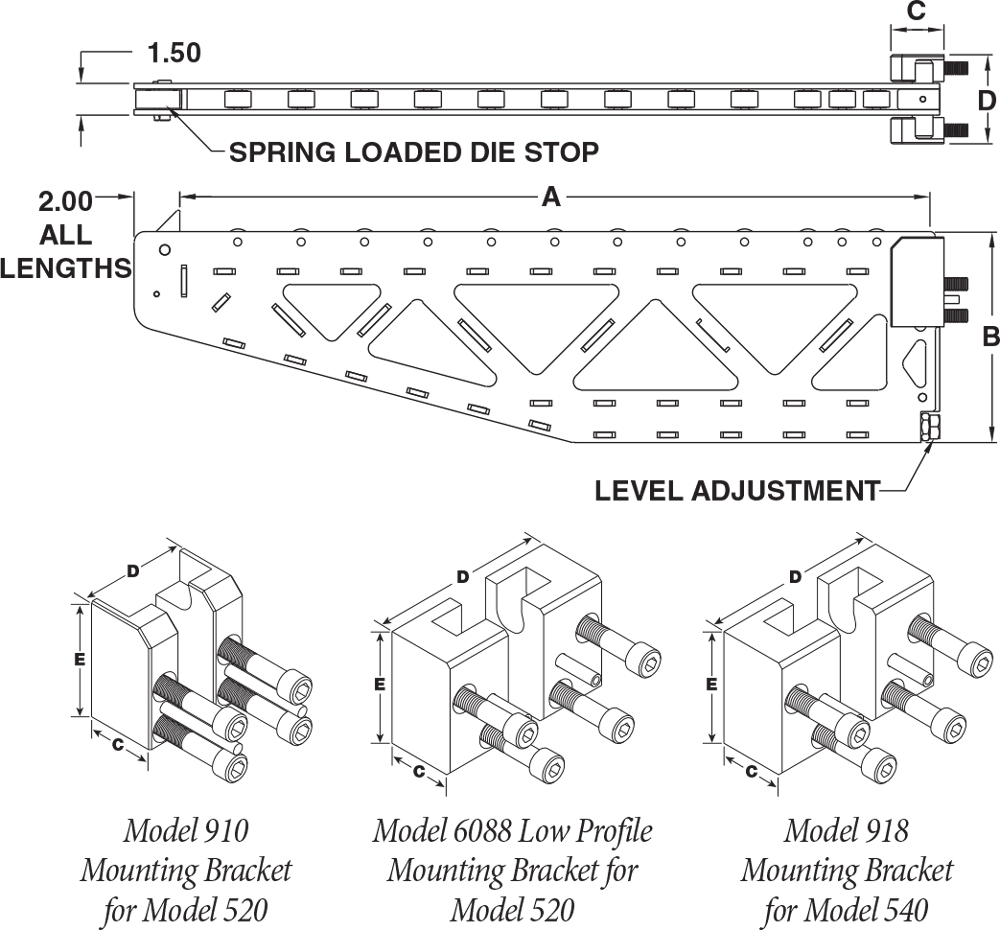

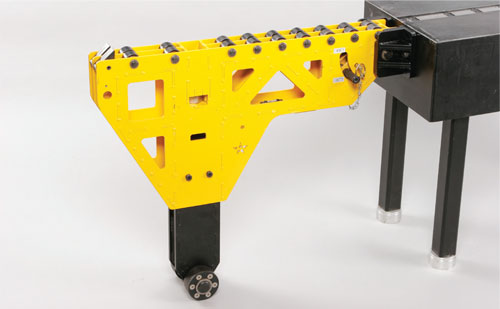

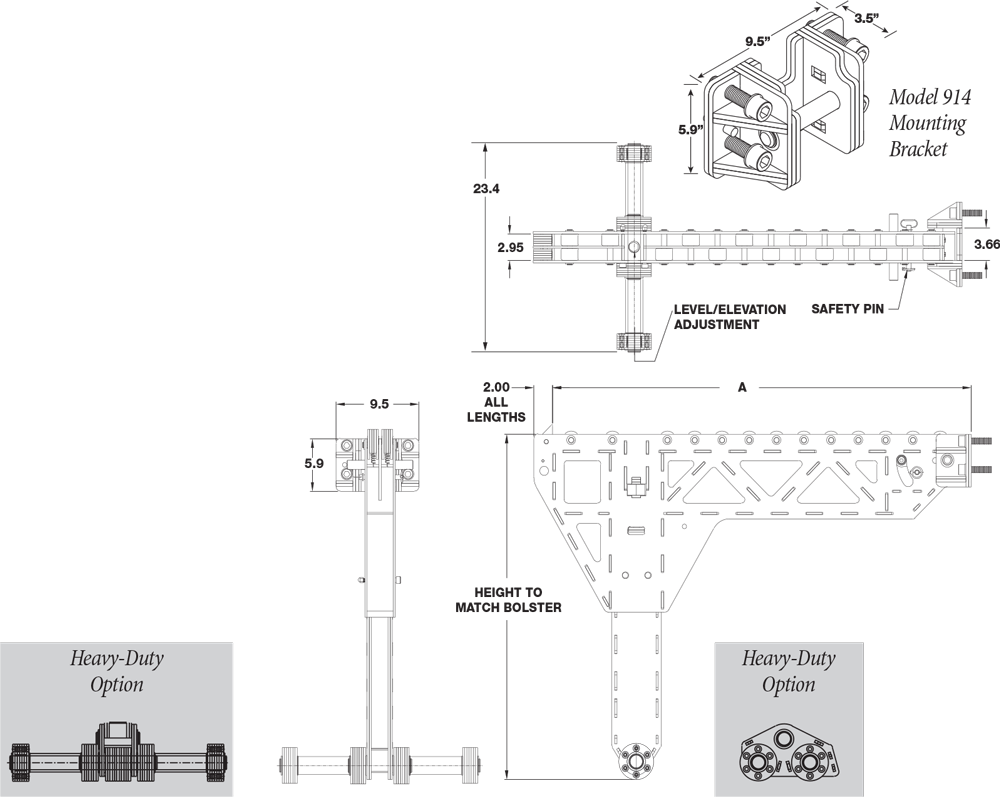

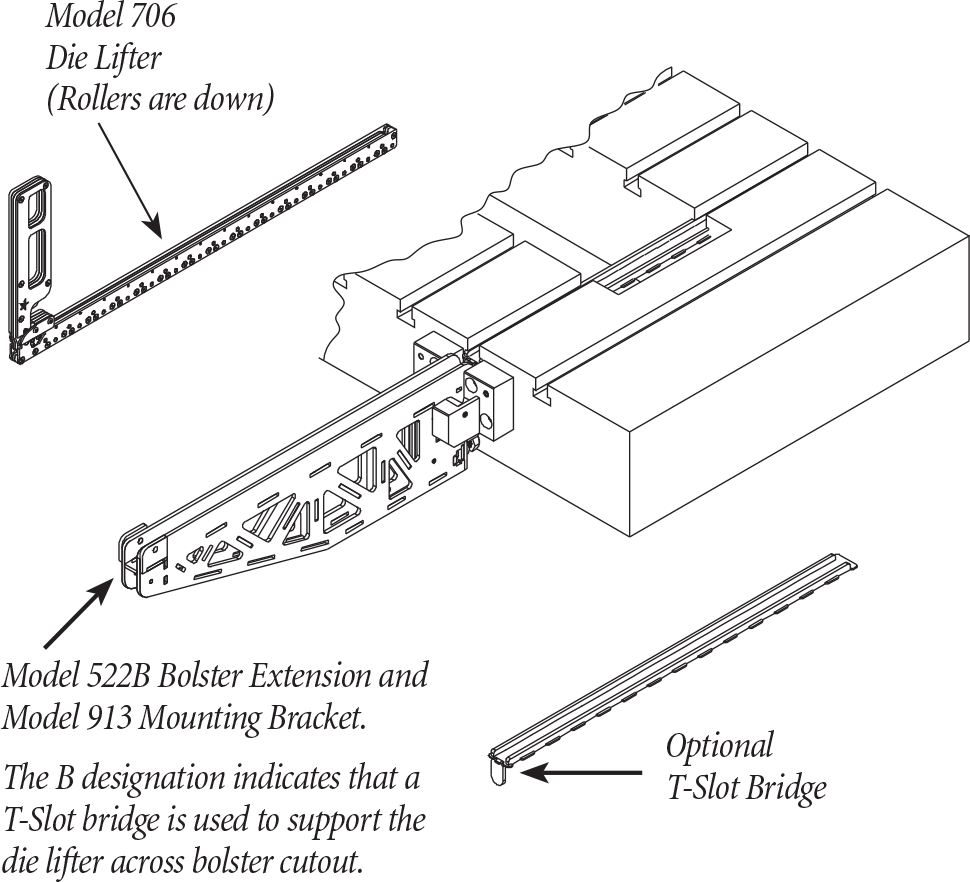

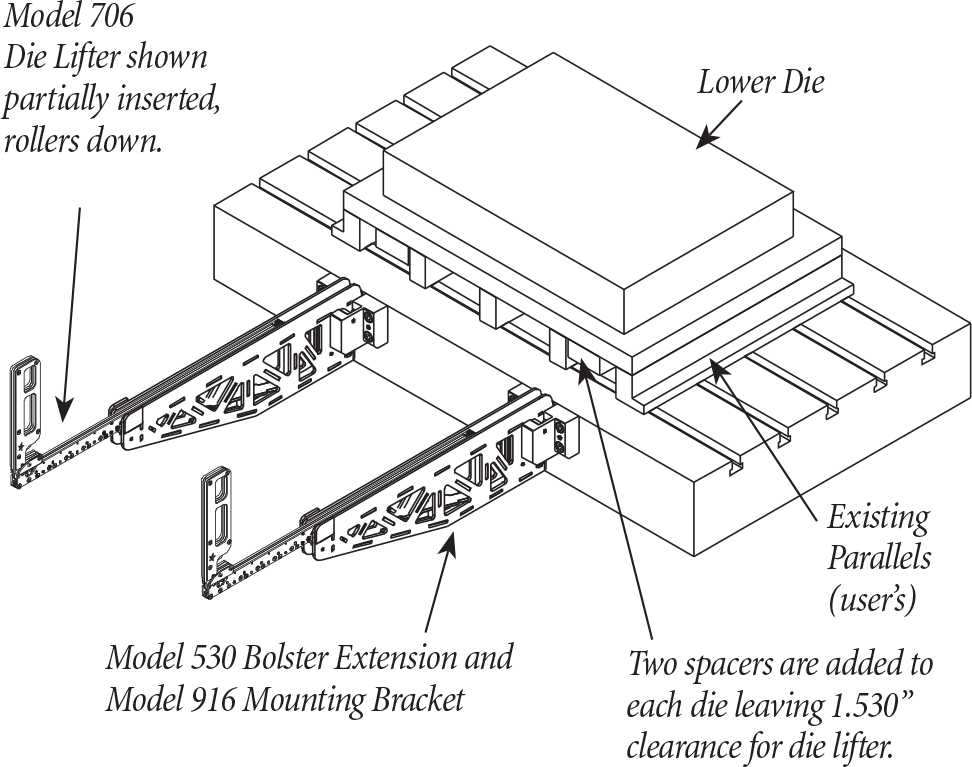

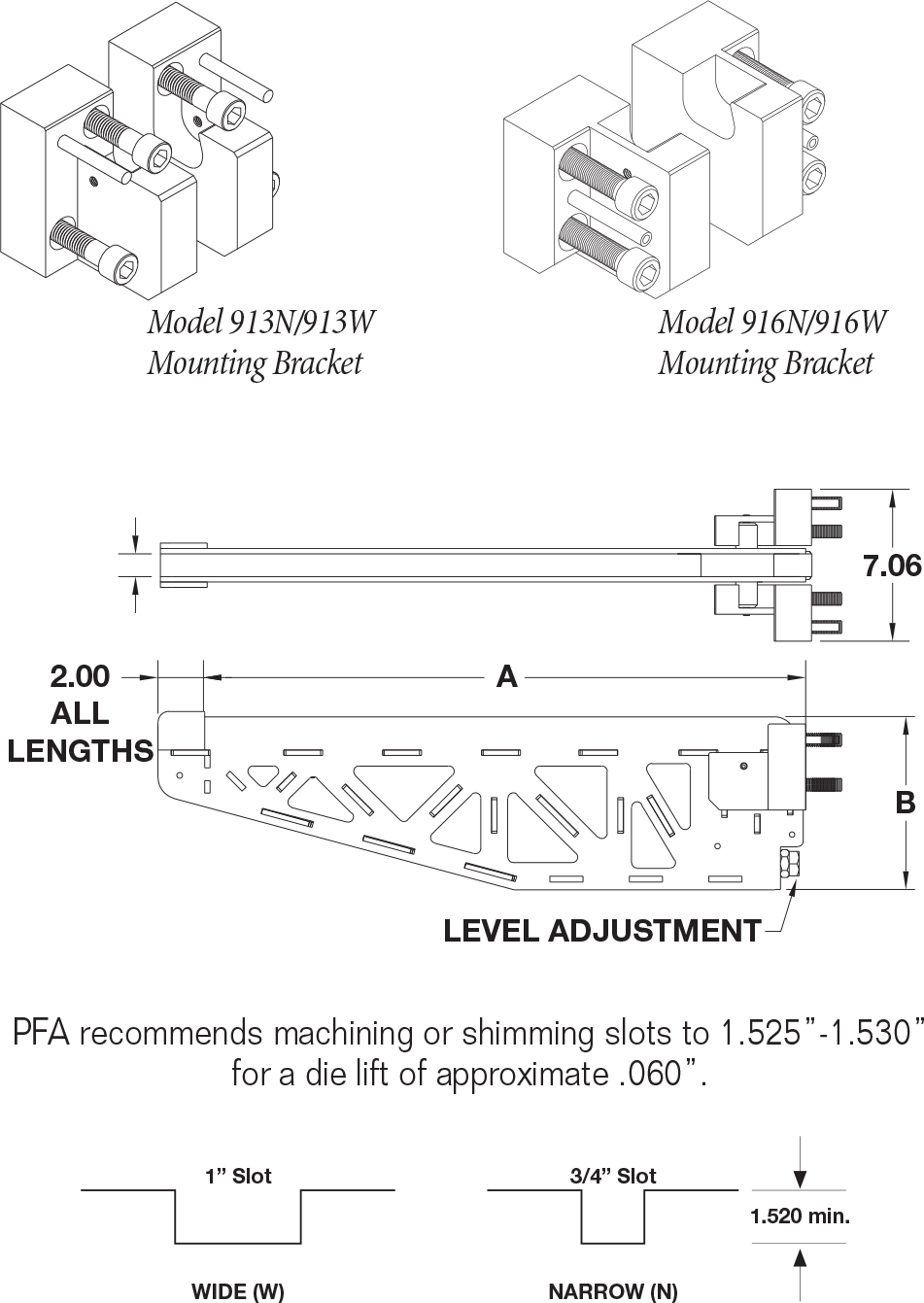

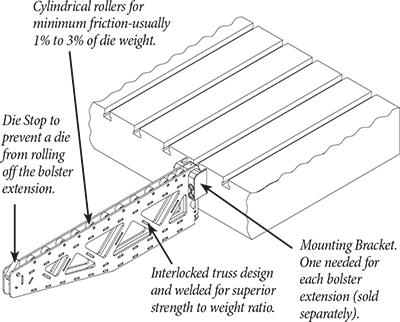

Mounting Options. Bolster Extensions are available in a variety of types: lift-off, swing-away, detachable, traveling and slotless. PFA can easily customize mountings to meet most applications and can even provide complete custom solutions.

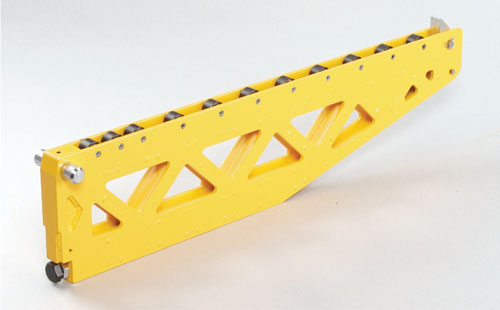

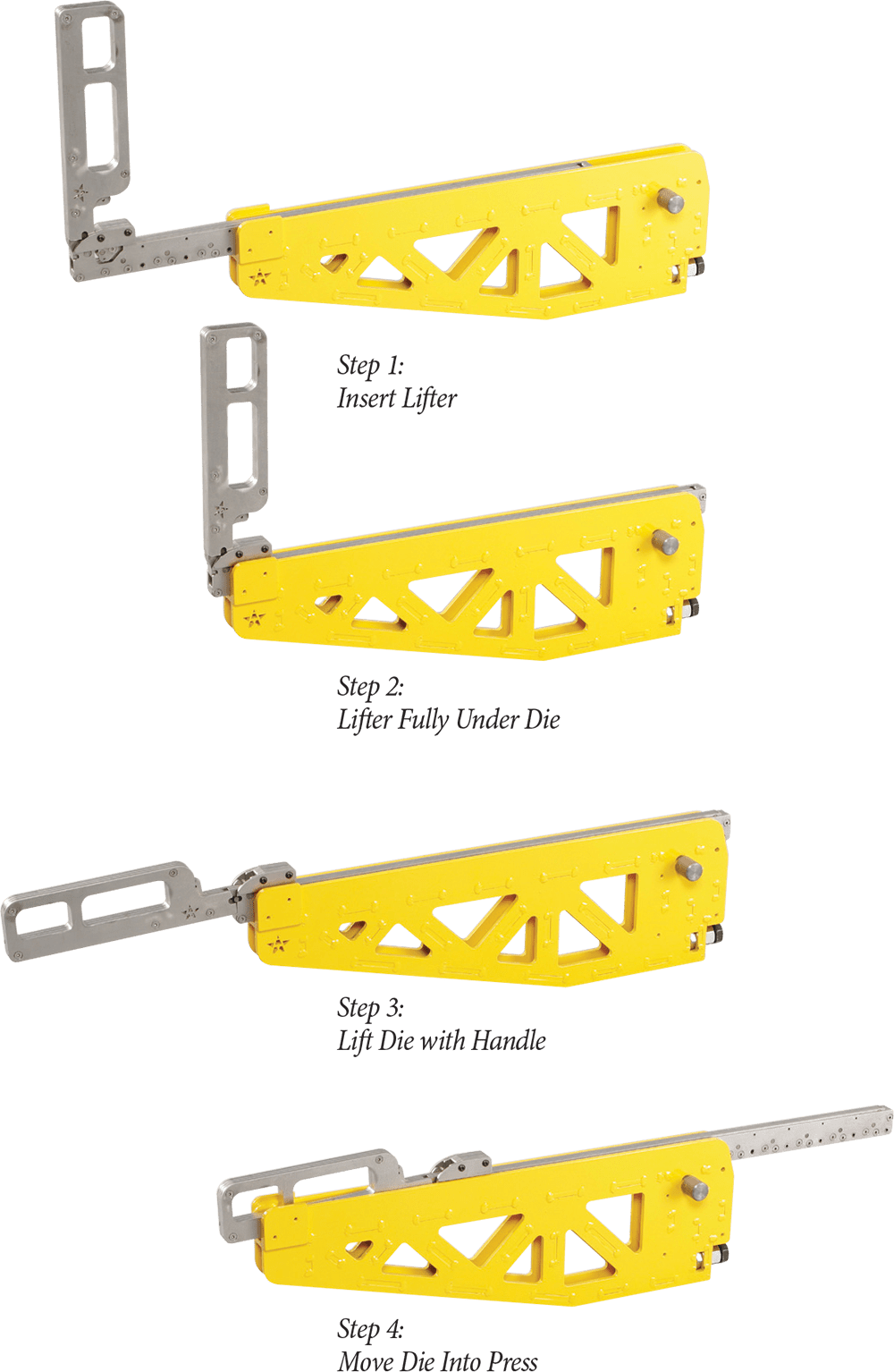

Fast and Easy. Cylindrical rollers on Bolster Extensions typically reduce the force necessary to move a die to about 1 to 3 percent of die weight. Moving the die into the press becomes fast and easy. Loading and unloading dies from Bolster Extensions is also easily done by forklift or crane, making extensions essential components of many Quick Die Change (QDC) systems.

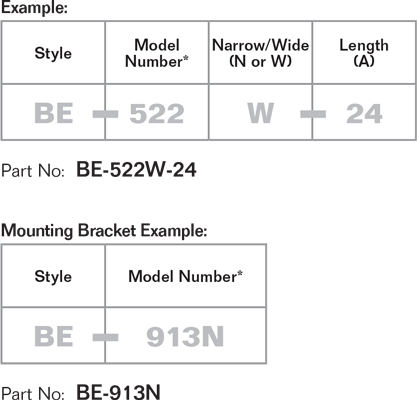

Modular. By reviewing multiple press needs at one time, common QDC components can be selected. Bolster Extensions can often be used on more than one press, greatly saving on the per press cost of QDC.