Introduction

In the fast-paced world of manufacturing, adaptability and efficiency are paramount. Production flexibility can make or break a business’s ability to meet market demands, reduce costs, and increase profitability. Among the modern solutions that enhance production flexibility, Quick Mold Change (QMC) Systems stand out as a game-changer. These systems facilitate rapid switching between molds, allowing manufacturers to adjust swiftly to changing demands and product variations.

In this blog post, we’ll delve into the intricacies of Quick Mold Change Systems and explore their profound impact on production flexibility. By the end of this read, you’ll understand why investing in QMC systems is not just a trend—it’s a necessity in today’s manufacturing landscape.

Understanding Quick Mold Change Systems

So, what exactly is a Quick Mold Change System?

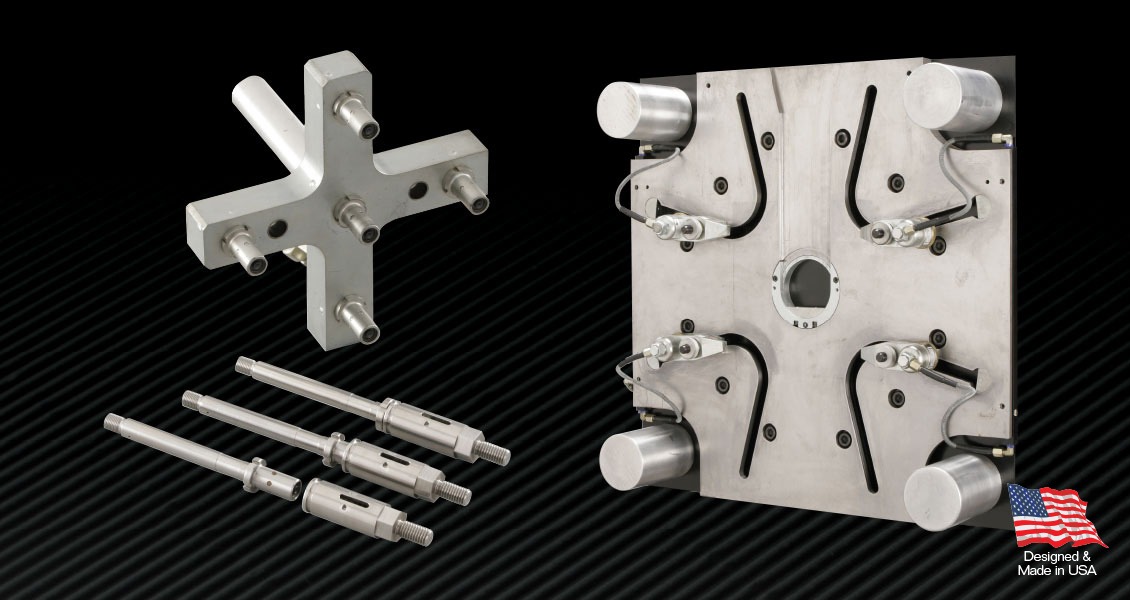

A Quick Mold Change System enables manufacturers to reduce the time spent switching molds on machinery, directly influencing production efficiency. Here are some key components that make up QMC systems:

- Quick-Release Mechanisms: Devices designed to allow rapid and safe mold removal.

- Modular Clamping Systems: Ensures consistent clamping force, thus improving mold positioning and reducing errors.

- Sensor Integration: Many QMC systems come equipped with sensors that provide real-time feedback on mold status, enhancing operational control.

- Customizable Solutions: Allow for tailoring the system to the specific needs of various manufacturing processes.

QMC systems are prevalent in industries that rely heavily on mold-based processes, such as injection molding, die casting, and automotive manufacturing. The ability to shorten changeover times translates directly to increased productivity and versatility.

Benefits of Quick Mold Change Systems

Adopting Quick Mold Change Systems offers numerous advantages that can significantly enhance a manufacturing operation’s flexibility:

- Reduction in Downtime

One of the most appealing benefits of implementing QMC systems is the drastic reduction in downtime during mold changeovers. Traditional mold changing processes can take hours, but QMC systems can reduce this time to mere minutes.

-

- Fast Changeovers: Many QMC systems can halve the time it takes to switch molds, ensuring your machines spend more time producing and less time idling.

- Streamlined Operations: The simplified process not only speeds things up but also minimizes the potential for errors during changeovers.

- Increased Production Capacity

With reduced downtime, manufacturers can increase their overall production capacity.

-

- Higher Output: More production cycles mean higher output, allowing businesses to meet customer demand without overextending resources.

- Scalability: QMC systems allow businesses to scale operations up or down easily, accommodating varying production runs as needed.

- Enhanced Product Variety

In an environment where consumer preferences shift rapidly, being able to offer a diverse product range is crucial.

-

- Quick Adaptation: QMC systems enable manufacturers to quickly switch molds to produce different products, allowing them to respond to market trends effectively.

- Customization: Businesses can introduce new products without a lengthy setup time, improving their market competitiveness.

- Cost Efficiency

Over time, Quick Mold Change Systems can result in substantial cost savings:

-

- Labor Cost Reduction: Less time spent on mold changes means reduced labor hours, translating to lower labor costs.

- Maximized Machine Utilization: Efficient mold changeovers mean machines stay operational longer, ensuring a better return on investment.

Factors Influencing Production Flexibility with QMC Systems

While Quick Mold Change Systems provide numerous benefits, certain factors affect how effectively a manufacturing operation can leverage them:

- Design and Compatibility

-

- System Design: The design of the QMC system is critical. Systems should be compatible with existing machinery to avoid unnecessary complications.

- Industry-Specific Solutions: Manufacturers should look for QMC systems customized for their specific operational needs, ensuring seamless integration.

- Training and Implementation

Investing in a QMC system without proper training is like buying a race car but never learning how to drive.

-

- Skill Development: Employees must be well-trained to utilize QMC systems fully, ensuring that they can maximize the technology’s benefits.

- Onboarding Procedures: A solid onboarding process for new systems can significantly boost operational efficiency.

- Integration with Automation Technologies

QMC systems shine when integrated with other automation technologies:

-

- Robotic Systems: Pairing QMC with robotics allows for even faster and more precise mold handling.

- PLC Systems: Programmable Logic Controllers (PLCs) can provide added control and monitoring, further enhancing operational efficacy.

Real-World Applications of QMC Systems

Let’s explore how various manufacturing scenarios benefit from Quick Mold Change Systems:

- Automotive Industry: In automotive manufacturing, where precision and quick adaptations to new models are essential, QMC systems support rapid adjustments without sacrificing quality.

- Consumer Goods: Brands in the consumer goods sector often face seasonal trends and rapid product launches. QMC systems enable quick transitions between molds, allowing these companies to adjust their offerings swiftly.

- Medical Devices: In the medical field, regulatory requirements demand precision and reliability. QMC systems ensure minimal downtime while maintaining the highest production standards.

Manufacturers from these sectors have reported that implementing QMC systems has not only enhanced production speed but also improved employee satisfaction, thanks to streamlined processes and reduced frustration during mold changes.

Future Trends in Quick Mold Change Technology

As technology evolves, so do Quick Mold Change Systems. Here are some future trends to keep an eye on:

- IoT and Smart Technology Integration: The future of QMC systems lies in connectivity. Using Internet of Things (IoT) technology can enable real-time monitoring, predictive maintenance alerts, and optimization of the entire changeover process.

- Data-Driven Insights: Advanced QMC systems will provide analytics that helps manufacturers understand patterns, predict maintenance needs, and improve overall operational efficiency.

- Sustainable Practices: With growing emphasis on sustainability, future QMC systems are likely to incorporate eco-friendly materials and processes that align with the industry’s environmental goals.

Conclusion

The adoption of Quick Mold Change Systems is revolutionizing the manufacturing landscape. These systems enhance production flexibility, enabling businesses to adapt quickly to market trends, reduce downtime, increase capacity, and improve cost efficiency. As manufacturers increasingly face challenges in competitive markets, investing in QMC technology is no longer just a choice—it’s a strategic necessity.

If your manufacturing business has not yet embraced Quick Mold Change Systems, now is the time to consider the benefits it can bring to your operations. Embrace the future of manufacturing and boost your production flexibility with advanced QMC solutions!