DIE-LOK Multi Slide Systems is a revolutionary new die-casting system that revolutionizes how die-casting is done. The system is designed to reduce labor costs, cut down on waste, and increase production efficiency. It is an ideal solution for die-casting applications that require quick cycle times, intricate internal features, and complex external features.

What is the DIE-LOK Multi-Slide System?

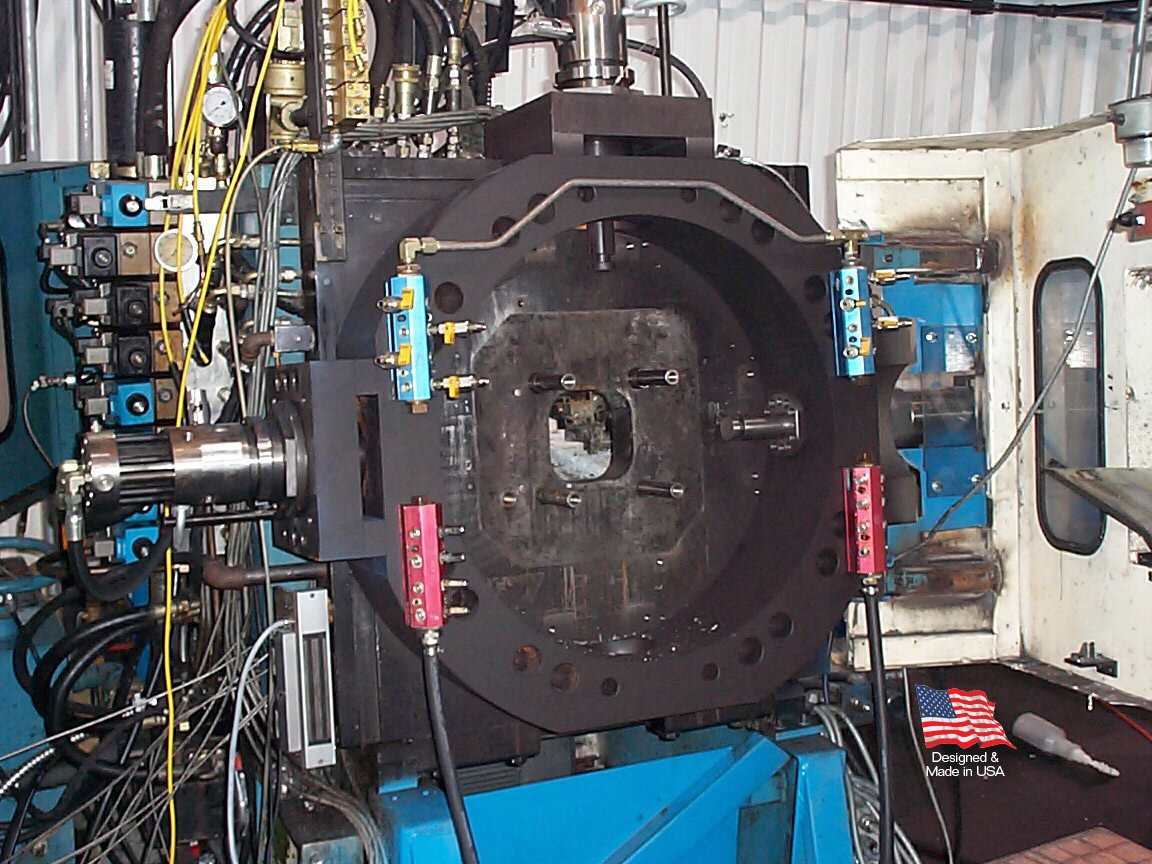

The DIE-LOK Multi Slide System consists of an advanced die-casting machine, a unique slide system, and a unique die-casting mold. The machine is designed with a high-speed electric motor capable of producing up to 300 parts per minute.

The unique slide system moves the die-casting mold along a linear path, allowing for the production of intricate components with multiple cavities. In addition, the system features an automated system for controlling the temperature of the die-casting process, allowing for precise control of the size and shape of the resulting components.

The DIE-LOK Multi Slide System is designed to be easy to use and reliable. The system has built-in safety features, such as an integrated emergency stop button and an auto-shutdown feature. In addition, the system is designed to be low maintenance and energy efficient. This is achieved through low-resistance bearings, automated lubrication systems, and a low-power electric motor.

Advantages Gained by Using the DIE-LOK Multi-Slide System

The DIE-LOK Multi Slide System offers several advantages over traditional die-casting systems. For example, the system can produce parts with a higher level of complexity and accuracy. Furthermore, the system can produce parts with multiple cavities, which can be used to reduce labor costs and increase production efficiency.

The DIE-LOK Multi Slide Systems is an ideal solution for die-casting applications that require quick cycle times and intricate internal and external features. The system is designed to be reliable, energy-efficient, and low maintenance. In addition, the system can produce multiple components with intricate details, allowing for reduced labor costs and increased production efficiency. For these reasons, the DIE-LOK Multi Slide System is an ideal solution for die-casting applications!

For more information about this unique and innovative product, you are encouraged to visit the dedicated DIE-LOK Side-Action Systems page. Here you will find more information about how the product can be used and how it can upgrade your existing die-casting setup or complete your new system.

Why Choose PFA, Inc.?

PFA manufactures locking cylinders, and core pull cylinders for molds and dies; quick mold change and quick die change systems for injection molding, die casting, and metal stamping; locking and braking actuators/cylinders for work cell and heavy industrial applications; and robotic end-effectors, grippers, and gripper pads for robotic applications. Both off-the-shelf and custom solutions are available to make your application a success.