Air grippers, also known as pneumatic grippers, have been available commercially for only a few decades. Their most common purpose: to grasp or enclose parts for transfer, insertion, or assembly in automated manufacturing systems. Although, some are additionally used in environments too hazardous for human presence. The pneumatic gripper fingers, or jaws, open and close with pressure from a compressed air supply system that moves an inner piston.

Utilizing pneumatic grippers is cost-efficient and straightforward since most manufacturing facilities already have access to compressed air. Small, light, and low-cost, pneumatic grippers yield a substantial amount of gripping force with little maintenance required. Pneumatic grippers can provide millions of cycles without needing upkeep.

Available in a wide range of sizes, pneumatic grippers provide grip forces of only a few ounces to several hundred pounds. The air pressure determines the force of a gripper. If you increase the air pressure by 20 percent, you increase the force on the gripper by 20 percent. Alternatively, you can also reduce the gripper force when using an air regulator.

What to Consider When Choosing a Pneumatic Gripper:

There are several key factors to consider when choosing a pneumatic gripper. Keep in mind the shape, orientation, and dimension of the part. While a 2-jaw parallel gripper works well with an object with two opposing flat surfaces, jaws can also be designed to handle cylindrical objects. Additionally, there must be enough grip force to secure the object adequately; therefore, thought must be given to the force requirement.

There are two primary types of action performed by grippers: external and internal. External is the more common and simplistic method of holding objects and requires the shortest stroke length. When the gripper’s fingers close, the closing force of the gripper holds the object. In some applications, the object will need to be held from the center, known as internal action, to allow access to the exterior of the object. This is why the accessibility of the object must be considered when selecting a gripper.

The environment in which the gripper will function is also important to keep in mind. Some grippers are specifically designed for harsh environments or cleanroom applications. And lastly, it is imperative to consider the retention of the object. A gripper will relax its grip on an object when air pressure is lost. This may cause the object to be dropped. To counter this issue, a spring assist gripper may be the best choice.

Choose the Right Gripper For Your Automated Process

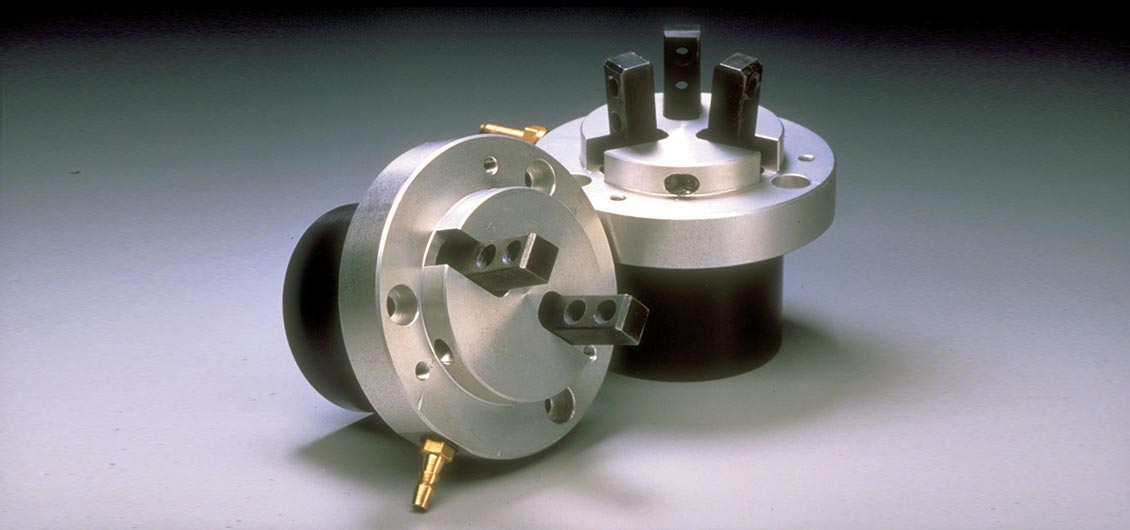

Single Acting Robotic Grippers:

Lightweight with multiple jaw configurations, the GTP-45 delivers 600# of grip force. Designed to accommodate added tooling on the fingers and grip complex components, this style is excellent for ID and Inside Bore applications.

Double Acting Robotic Grippers:

Designed to allow compressed air to both open and close, this type of gripper allows internal and external clamping. And with a spring assist feature, the workpiece is held in place even if air pressure is lost. The DAG-80 offers 1,000# of grip force, the DAG-45 provides 800# of grip force, while the DAG-30 yields 250# of grip force.

APG Double Acting Parallel Jaw Grippers:

Weighing only .5 lbs., the APG-30 is lightweight with a grip force of 28 lbs. At 100 PSI air pressure. The APG-45 is similar, with a weight of 1.1 lbs. And 85 lbs. of grip force while the APG-80 weighs in at 6.1 lbs. with a grip force of 250 lbs. Accepted for cleanroom use, the APG-30 and 45 run with zero particle problems.

Why choose PFA for your automation solutions?

If your robot tooling needs to be able to pick up, manipulate, and place products, then you are going to need a robotic gripper. PFA offers some of the highest force-to-weight ratio grippers to make your application a success. With so many types, sizes, and configurations on the market, it can be daunting when selecting the optimum gripper for your robot tool. Let us help you get a grip on your automation system by contacting ustoday or calling 262-250-4410.