End effector, or End-of-Arm Tooling (EOAT), is essentially every robot’s “business end.” It can be used to describe any device attached to the end of a robotic arm. While there are hundreds of different end effectors available from many different manufacturers, there are some basics to consider when choosing the best fit for your robotic system.

What is an End Effector?

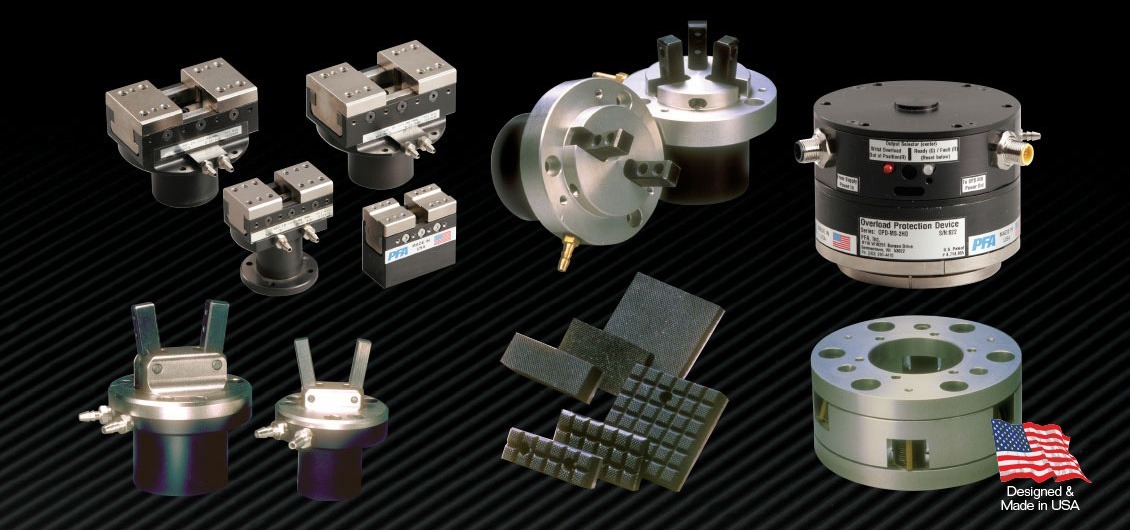

An end effector, a peripheral device attached to the robot’s wrist, allows the robot to interact with its task. EOATs are mechanical or electromechanical while functioning as either grippers, process tools, or sensors. End effectors range from two-fingered grippers for simple pick-and-place functions, while others are complex systems for robotic inspections.

Robots are practically useless without the end effector. Though an articulated robotic arm may be programmed to a particular location within its workspace, it cannot perform its operation without an end effector.

What are the types of EOATs?

- Grippers are the most common robot end effectors. A gripper allows a robot to pick up and manipulate objects, making them best suited for pick-and-place, machine tending, and assembly tasks.

While there are more different types of grippers than any other type of EOAT, fingered grippers are by far the most popular. Fingered grippers come with two, three, four, or five fingers though it is possible to use a gripper with six fingers. However, this is rarely necessary.

Beyond finger grippers, there are vacuum grippers, magnetic grippers, needle grippers, and many more developed continually.

- Process tools are like workers operating power tools. Unlike a gripper that can only grasp an object, a process tool actually changes the workpiece. Because there are different operations in manufacturing, there are also several process tools, including robot welding tools, robot painting tools, robot machining tools, 3D printing tools, and many more.

If a human can do it with a power tool, most likely, a robot can do it with a process tool.

- Sensors attach to the robot to use as a programmable sensor-orientation device. This is useful in applications such as robotic inspection by reducing the amount of hands-on time inspection engineers must spend collecting data.

Many sensors serve as end effectors, including laser scanners, ultrasonic sensors, 2D and 3D cameras, and infrared sensors like those used at NASA.

How to Select the Right End Effector.

- Determine the actions the robot needs to perform.

- Review the types of end effectors that can deliver these actions.

- Evaluate each type for complexity, cost, and other pertinent factors.

- Keep in mind that there may be several ways to achieve the same task utilizing different EOATs.

- Select the end effector best suited for the needs of the task.

How to Use an EOAT with the Robot.

Because end effectors use different communication protocols, different programming interfaces, and require diverse skill levels, each end effector is operated slightly differently. However, there are basic steps for utilizing any end effector with a robot:

- Mount the end effector onto the robot’s wrist.

- Attach power connections such as electric, pneumatic, or hydraulic.

- Attach communication interfaces between the end effector and robot controller or computer.

- Incorporate the EOAT’s programming into the robot’s program.

Why Choose PFA for your Automation Solutions?

If you have robotic tooling, then you are going to need an end effector. With so many types, sizes, and configurations on the market, it can be daunting when selecting the optimum EOAT for your robot tool. PFA’s team works to determine the best end-of-arm tooling for your application, design, and most importantly, your part or product. Let us help you handle your automation system’s “business end” by contacting us today or calling 262-250-4410.