Known as a cam pin, angle pin, horn pin, etc., the Cam Pin Slide is the most common and versatile of all slide mechanisms. It is driven by the opening of the press. The action of the angled pin withdrawing from the angled hole drives the slide back. Springs hold the slide in the retracted position. Upon press closing the cam pin returns to drive the waiting slide back almost to molding position. Finally then the lock seats against the back of the slide, driving it to its home position and clamping it there for the duration of the next shot.

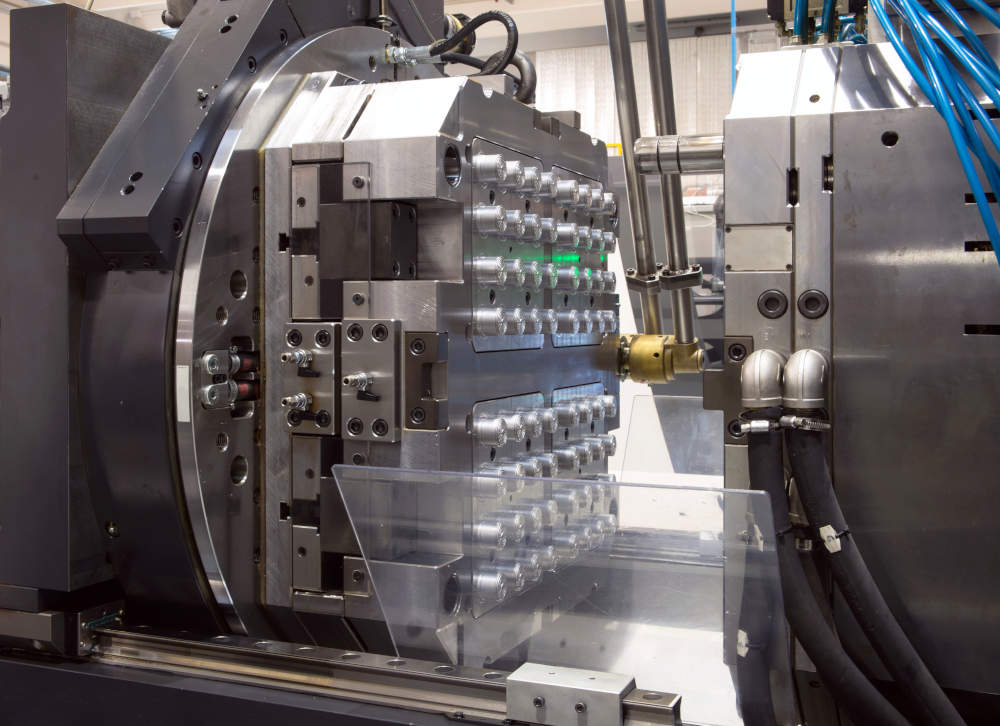

Since many injection molded products have special requirements, a mold side-action or slide is often used to form complex geometries and release the finished product upon mold opening. To achieve this, a “slide” or “slider” is often used as a core-pulling mechanism. At its most basic level, the slider is used to turn the vertical movement of the mold opening or closing into horizontal motion.

Slide mechanisms are typically composed of a few basic components including a forming surface, slider body, guide pin, wedge, press block and wear plate. During operation, the injection mold slider is subject to wear and tear and surface nitriding will often be performed to minimize some of the damage and preserve the components longer. Although, the most interesting part of working with a slider is producing complex geometries, an additional challenge is being able to prevent displacement that may occur from the pressure generated throughout the injection molding process.

A great review of a variety of slide mechanisms can be found at Parallel Design’s website.

Since sliders can move during production without the right level of hydraulic pressure being applied, many manufacturers experience waste or excessive flashing on their completed parts. For this reason, it is important to invest in a locking mechanism that can help reduce “back up” that creates discrepancies and ensure pressure remains constant even at zero PSI. An appropriate locking device will also ensure an injection mold slider can not only travel the required distance, but also provide a safe return to its set position.

How Can KOR-LOK® Preload Functionality Help?

Since the injection mold slider requires a perfect fit and large backup mass or a constant pressure to ensure the finished product does not have excessive amounts of flash or other defects caused by movement, preloading your cores can be a significant advantage. Preloading and Locking cylinders help create large forces on the slide and maintain that force at zero PSI. At PFA, we feel understanding core forces under injection, understanding the required preload necessary to overcome those forces, and knowing the operation of possible solutions, is critical to choosing the correct “locking” cylinder. KOR-LOK® not only preloads, it fully locks. 100% preload at zero PSI proves it.

In the past, core applications required choosing the best REACTIVE method available, reacting to force but not applying it. If it is not applied force, it is not maintaining position. KOR-LOK®’s PROACTIVE Technology™ and 100% applied force provides you with the advantages of Zero Flash™, Zero Flex™ performance. This, in turn, makes it the perfect accompaniment for any injection molding system that requires the use of a slider for normal or efficient operation.

KOR-LOK® Side-Action Systems provide large pre-loads and thermal compensation to core slides by use of an internal tapered locking mechanism. The threaded housing provides a base to support the locking mechanism and transfer load between the mold and the core slide. With a minimum of 1,500 psi hydraulics, KOR-LOK® Side Action Systems can provide 100% preload to a rated load to not only lock but “super lock” to ensure hydraulics are no longer needed. If you are interested in learning how KOR-LOK® can improve your injection molding processes and enhance the performance of your injection mold slider, we would love to talk!