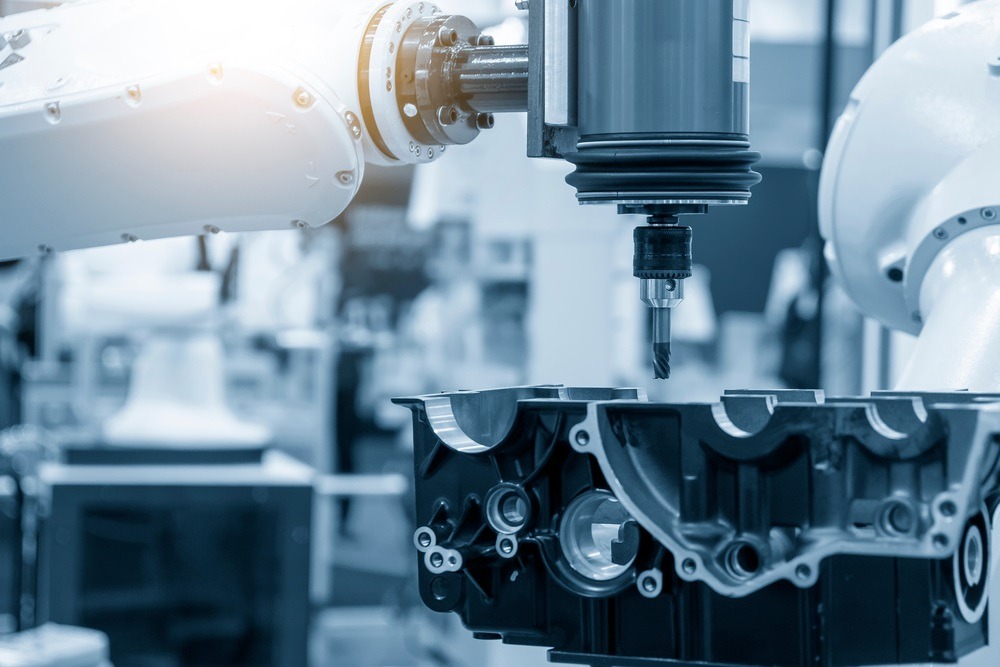

End-of-arm tooling, also known as EOAT, is a specialized tool used in robotic systems to aid in the manipulation of materials and objects. This type of tooling can be used for a variety of applications, including pick and place, assembly, testing, and material handling. When selecting an end-of-arm tool, it is important to consider the size of the robot arm, the type of materials that need to be handled, and the environment in which the robot will be used. There are a variety of end-of-arm tooling options, including vacuum grippers, mechanical grippers, and pneumatic grippers. Each type of gripper has its own advantages and disadvantages, so it is important to select the best option for the application.

In addition to the grippers, there are a variety of accessories that can be used with end-of-arm tooling. These include sensors, safety features, and control systems. It is crucial to consider these features when selecting the end-of-arm tooling, as they can have a big impact on the performance of the robot.

When selecting the best end-of-arm tooling for an application, it is vital to understand the application requirements. This includes the size and weight of the object, the environment, and the speed and accuracy that is required. It is also essential to consider the overall system requirements, such as power and maintenance requirements.

The Schneider Company has created a comprehensive guide to end-of-arm tooling that covers all aspects of the selection process. This guide provides an in-depth look at the different types of end-of-arm tooling, their advantages, and disadvantages, as well as the accessories and control systems. This guide also includes information on safety and maintenance requirements, as well as how to select the best end-of-arm tooling for the application.

The Complete Guide to End-of-Arm Tooling from Schneider Company is an invaluable resource for anyone looking to purchase end-of-arm tooling. It provides an in-depth look at the different types of tooling, their advantages and disadvantages, and the accessories and control systems. This guide also includes information on safety and maintenance requirements, as well as how to select the best end-of-arm tooling for the application. This guide is a must-have for anyone looking to purchase end-of-arm tooling.

How Can PFA, Inc. Help?

Take the first step in optimizing your production and get to know more about End-Of-Arm Tooling by exploring PFA Inc.’s extensive selection of products and services! With decades of expertise in the automation field, PFA Inc. provides the perfect solution for any of your End-Of-Arm Tooling needs. Visit their website now to learn more and get started on your automation journey!